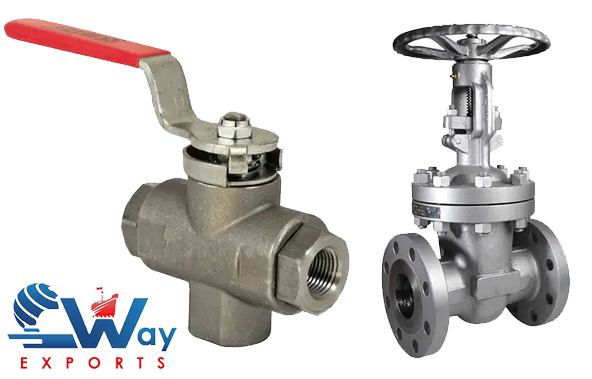

When it comes to industrial applications, choosing the right valve is crucial for optimal performance and efficiency. Two popular options that often come into consideration are ball valves and gate valves. Both valves have unique characteristics and advantages that make them suitable for various scenarios. In this article, we will explore the pros and cons of ball valves and gate valves, enabling industrial purchase professionals to make informed decisions and ensure smooth operations.

Ball Valves

Ball valves are known for their reliability and versatility. They feature a spherical disc with a hole in the middle that controls the flow of fluids. Here are the key advantages and disadvantages of ball valves:

Pros:

a) Quick and Efficient Operation: Ball valves offer fast and easy operation, allowing for quick opening and closing. This feature is particularly beneficial in applications that require frequent and precise control over flow rates.

b) Excellent Shut-Off Capability: Ball valves provide tight shut-off, minimizing the risk of leakage. The sealing mechanism ensures a secure closure, making them ideal for critical systems where leak prevention is paramount.

c) Versatile, well suited for a broad spectrum of applications Ball valves exhibit remarkable performance in high-pressure and high-temperature environments. These valves offer compatibility with a wide range of fluids, encompassing gases, liquids, and even corrosive media.

Cons:

a) Restricted Flow Control: While ball valves offer excellent shut-off capability, their flow control is limited. They typically operate in either fully open or fully closed positions, making them less suitable for applications that require precise throttling.

b) Higher Torque Requirements: Large-sized ball valves may require higher torque to operate due to the pressure on the sealing mechanism. This factor should be considered when selecting a valve for a specific application.

Gate Valves

Gate valves are popular for their robustness and ability to handle high-pressure systems. They feature a sliding gate-like disc that controls fluid flow. Let’s examine the pros and cons of gate valves:

Pros:

a) Full Flow Control: Gate valves provide excellent flow control due to their linear motion mechanism. They can be partially opened or closed, allowing for precise regulation of flow rates. This feature makes them suitable for applications that require throttling.

b) Minimal Pressure Drop: Gate valves offer minimal resistance to fluid flow when fully open, resulting in a lower pressure drop across the valve. This characteristic is advantageous in high-pressure systems where energy efficiency is crucial.

c) Durability: Gate valves are highly durable and can withstand harsh operating conditions, such as high temperatures and abrasive fluids. Their robust construction makes them suitable for long-term usage and reduces maintenance requirements.

Cons:

a) Slow Operation: Gate valves typically have a slower opening and closing time compared to ball valves. This factor should be considered in time-sensitive applications that require rapid response.

b) Prone to Leakage: Gate valves may be susceptible to leakage, especially in the partially closed position. Proper installation and maintenance are essential to ensure a reliable seal and prevent leakage issues.

Conclusion:

Both ball valves and gate valves offer distinct advantages and disadvantages, making them suitable for different industrial applications. Ball valves excel in quick operation, excellent shut-off capability, and versatility, while gate valves shine in precise flow control, minimal pressure drop, and durability. Industrial purchase professionals should carefully evaluate the requirements of their specific systems and consider factors such as flow control needs, pressure conditions, and maintenance considerations before selecting the most appropriate valve type. Selecting the right valve is a crucial step in ensuring smooth operations and minimizing downtime, making it a worthwhile investment for any industrial setting.

If you have any further questions or need assistance in selecting the ideal valve for your industrial application, our knowledgeable team is ready to help. At C-Way Engineering Exports, we are committed to delivering exceptional customer service and providing high-quality valve solutions tailored to your specific needs. Don’t hesitate to get in touch with us to ensure the success of your industrial operations.