Compare flow, pressure drop, pigging & cost for the right valve choice

If you’ve been involved in piping projects, whether in oil & gas, water treatment, HVAC, or chemical processing, you’ve definitely come across the terms full bore ball valve and reduced bore ball valve. At first, the difference sounds simple—one is “bigger,” the other is “smaller.” But the real decision isn’t that straightforward.

Choosing between the two can have a big impact on flow efficiency, cost, pressure drop, and even maintenance requirements. Pick the wrong one, and you could be paying more than necessary or compromising your system performance.

So, let’s dive into what each type means, where they’re best applied, and how you can make the right choice for your project.

What is a Full Bore Ball Valve?

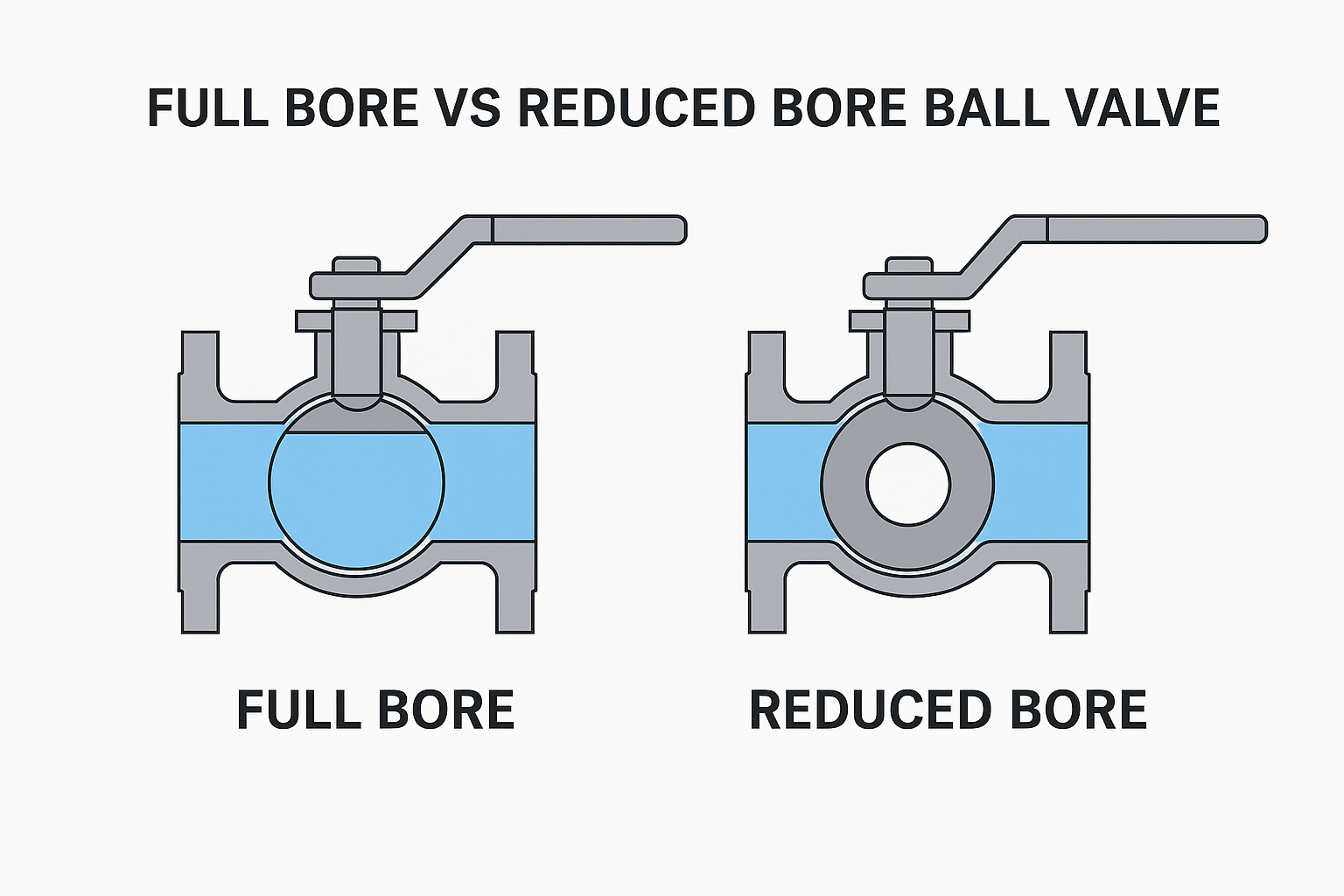

A full bore ball valve (also widely called a full port ball valve) has a bore—the hole through the ball—that is equal to the internal diameter of the connected pipe. This design ensures unrestricted flow.

Key Characteristics of Full Bore Valves:

• The pipeline sees no reduction in cross-sectional area.

• Pressure drop is negligible, which is crucial in energy-intensive systems.

• The valve body is bulkier and more expensive since the ball has to be larger.

👉 Example: In a DN50 pipeline (2-inch pipe), a full bore valve will also have a bore of ~50 mm.

What is a Reduced Bore Ball Valve?

A reduced bore ball valve has a bore that is smaller than the inner diameter of the connected pipe. While flow restriction does occur, it’s often minor and acceptable in many applications.

Key Characteristics of Reduced Bore Valves:

• Slight pressure drop, but usually negligible in short piping runs.

• Compact and lightweight design, making installation easier.

• Lower cost, since less material is used.

👉 Example: In the same DN50 pipeline, a reduced bore valve might only have a bore of ~40 mm.

Full Bore vs Reduced Bore Ball Valves: Key Differences

| Feature | Full Bore Ball Valve | Reduced Bore Ball Valve |

|---|---|---|

| Bore Size | Equal to pipe ID | Smaller than pipe ID |

| Flow Capacity | Maximum, unrestricted | Slightly restricted |

| Pressure Drop | Almost zero | Noticeable but acceptable |

| Cost | Higher (more material, larger body) | Lower (cost-efficient) |

| Weight & Size | Bulkier | Compact and lightweight |

| Pigging Capability | Suitable (pigs pass easily) | Not suitable |

| Applications | Oil & Gas, chemical, food processing, slurry | HVAC, water supply, utilities, fire systems |

Advantages of Full Bore Ball Valves

1. Unrestricted Flow

The bore matches the pipeline diameter, ensuring maximum flow. This reduces energy costs in systems where pumps drive fluids long distances.

2. Pipeline Pigging Compatibility

In oil & gas and water transmission pipelines, cleaning or inspection devices (pigs) are required. Full bore valves allow them to pass without obstruction.

3. Reduced Turbulence

No sudden narrowing means less erosion, making full bore valves ideal for abrasive or high-viscosity fluids.

4. Critical Application Ready

Whenever fluid control involves safety, high investment, or hazardous chemicals, full bore valves are the preferred choice.

Advantages of Reduced Bore Ball Valves

1. Cost Savings

The smaller ball and body mean reduced manufacturing material, lowering overall valve cost. In large systems with hundreds of valves, the savings are significant.

2. Compact and Lightweight

Easier to handle during installation, especially in HVAC and building services where space is tight.

3. Acceptable Pressure Drop

For water distribution, air conditioning, or fire suppression systems, the slight pressure loss does not compromise performance.

Applications at a Glance

Here’s a quick selection chart:

| Application | Recommended Valve | Why? |

|---|---|---|

| Oil & Gas Pipelines | Full Bore | Pigging, unrestricted flow needed |

| Chemical Processing | Full Bore (critical lines), Reduced Bore (utilities) | Balance between safety and cost |

| Water Treatment Plants | Reduced Bore | Slight restriction acceptable, cost advantage |

| HVAC Systems | Reduced Bore | Compact, lightweight, cost-effective |

| Food & Beverage Processing | Full Bore | Hygiene + unrestricted cleaning flow |

| Power Generation | Both | Full bore for main lines, reduced bore for auxiliaries |

| Fire Fighting Networks | Reduced Bore | Lower cost, flow still sufficient |

Full Bore vs Reduced Bore: Choosing the Right One

So, which one should you pick?

• ✅ Go Full Bore when:

o Your process involves pigging or frequent cleaning.

o Pressure drop must be avoided at all costs.

o You’re handling abrasive, sticky, or hazardous fluids.

• ✅ Go Reduced Bore when:

o Budget matters more than maximum flow efficiency.

o Your system doesn’t require pigging.

o The application is general service: HVAC, utilities, water supply.

👉 Think of it this way:

• A full bore valve is like a wide highway—built for fast, efficient travel without bottlenecks.

• A reduced bore valve is like a city street—a bit narrower, but still gets you where you need to go, at lower cost.

Conclusion

Both full bore and reduced bore ball valves are crucial in industrial and commercial piping systems. The right choice depends on your balance of flow performance, system criticality, and cost efficiency.

• Full Bore Ball Valves → Maximum flow, pigging-friendly, best for critical services.

• Reduced Bore Ball Valves → Compact, cost-effective, ideal for non-critical services.

At the end of the day, it’s not about which one is “better”—it’s about which one is better for your application.

Looking for expert advice on ball valve selection?

At C-Way Engineering Exports, we manufacture and supply a full range of full bore and reduced bore ball valves, full port and reduced port ball valves in stainless steel, carbon steel, and lead-free brass. Our valves are engineered to meet international standards and serve industries worldwide, from the USA and Canada to Europe, the Middle East, and Australia.

Contact us today to request a datasheet, get a competitive quote, or speak with our technical team. We’ll help you choose the right valve for your system—no guesswork, just expertise.