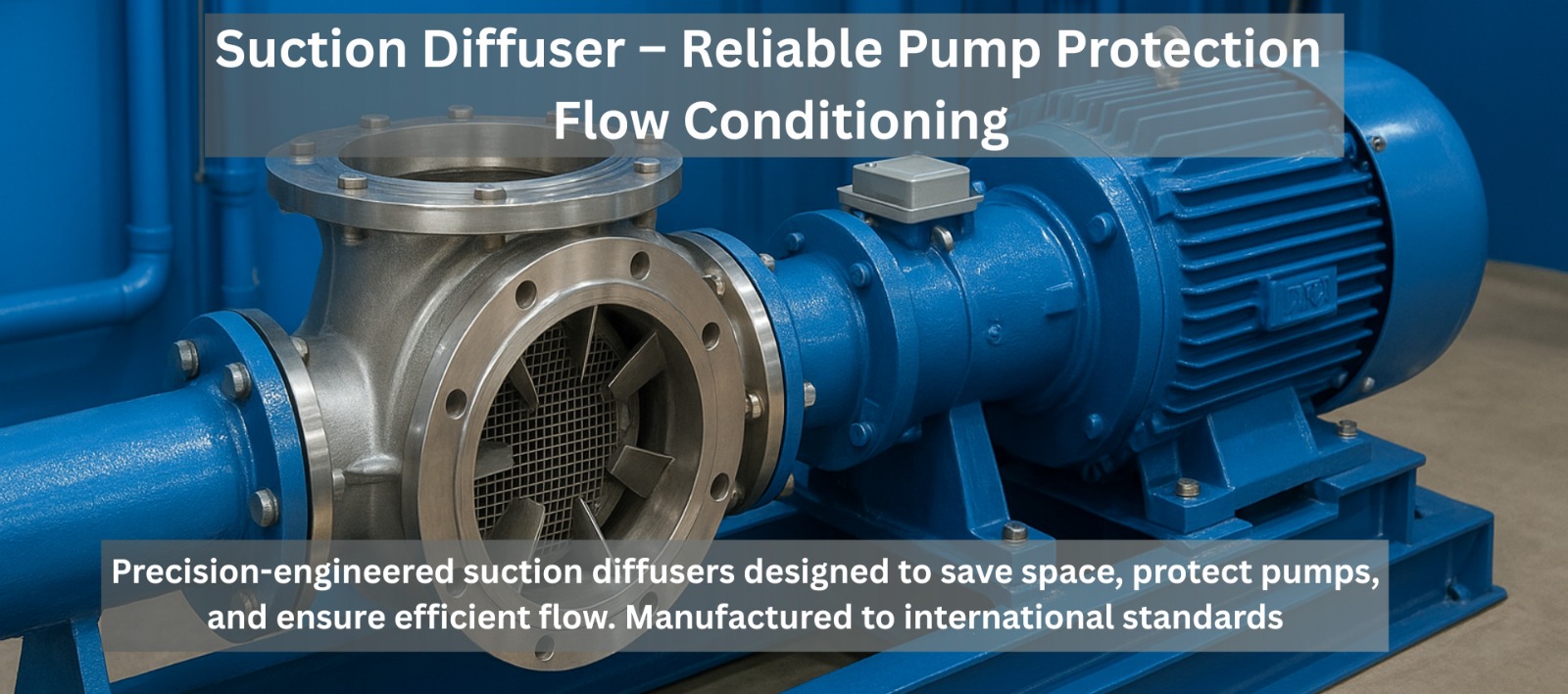

Precision-engineered suction diffusers designed to save space, protect pumps, and ensure efficient flow. Manufactured to international standards.

C-Way Engineering Exports is a trusted Suction Diffuser manufacturer, supplier, and exporter, delivering precision-engineered solutions for pump protection and efficient pipeline performance. With over 30 years of manufacturing expertise, we produce suction diffusers that integrate a strainer, flow straightener, and 90° elbow into one compact unit—eliminating the need for extended suction piping runs and reducing installation costs.

Our suction diffusers are designed to ensure uniform fluid flow at the pump inlet, minimizing turbulence, preventing cavitation, and extending the life of pumps and seals. Each unit is equipped with an internal strainer that removes solid particles and debris, safeguarding pump impellers and bearings against wear and failure.

Available in Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel (304, 316, 316L), and Duplex grades, our suction diffusers are built to perform under diverse operating conditions. They come in pressure ratings up to Class 300 / PN25, with temperature resistance from -20°C to +400°C, making them suitable for water, chemical, HVAC, process, and power plant applications.

As a global suction diffuser exporter, we manufacture products in strict compliance with ASTM, ANSI, EN, and DIN standards, while every unit undergoes hydrostatic and functional testing as per API 598 and EN 12266. This guarantees high reliability, superior efficiency, and long-term durability in industrial pumping systems worldwide.

Our suction diffusers are engineered with performance, durability, and ease of maintenance in mind. Every feature is designed to simplify pump installation while enhancing system reliability. Here’s how our design benefits your operation:

| Parameter | Specification |

|---|---|

| Size Range | DN 50 (2”) to DN 600 (24”) |

| Material Options | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel (304, 316, 316L), Duplex |

| Pressure Ratings | ANSI Class 150 / 300; DIN PN10 / PN16 / PN25 |

| Working Temperature | -20°C to +400°C (material dependent) |

| Strainer Aperture | Standard 3 mm, customized on request |

| End Connections | Flanged – ANSI B16.5, DIN EN 1092-1 |

| Testing Standards | Hydrostatic and functional testing as per API 598, EN 12266 |

| Manufacturing Standards | ASTM, ANSI, EN, DIN |

| Material Type | ASTM / ANSI Standard Available |

|---|---|

| Carbon Steel | ASTM A216 WCB, A105, A234 WPB |

| Stainless Steel | ASTM A351 CF8, CF8M; ASTM A182 F304, F316, F316L |

| Duplex Stainless | ASTM A890 4A, 5A; ASTM A182 F51, F53 |

| Cast Iron / Ductile Iron | ASTM A126 Class B, ASTM A536 Grade 65-45-12 |

| Material Type | EN / DIN Standards Available |

|---|---|

| Carbon Steel | DIN 1.0460 (C22.8), EN 10222-2 P245GH |

| Stainless Steel | DIN 1.4301 (X5CrNi18-10), DIN 1.4401 / 1.4404 (X5CrNiMo17-12-2 / X2CrNiMo17-12-2) |

| Duplex Stainless | DIN 1.4462 (X2CrNiMoN22-5-3) |

| Cast Iron / Ductile Iron | EN-GJL-250 (GG25), EN-GJS-400-15 (GGG40) |

Our suction diffusers are designed to perform reliably across diverse industries. By combining straining, flow straightening, and elbow configuration into one compact unit, they provide pump protection, reduce turbulence, and ensure system efficiency in a variety of industrial applications.

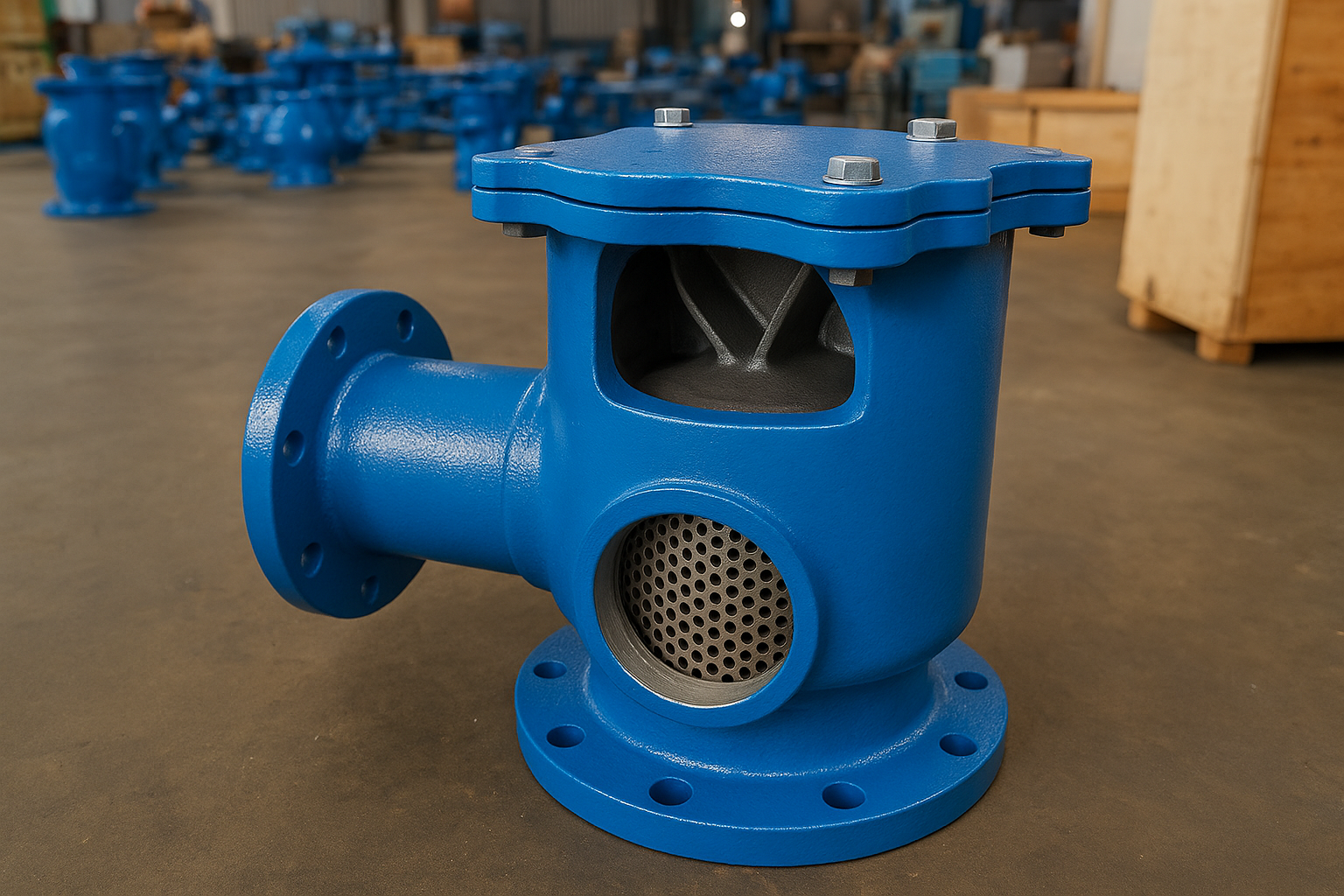

A Suction Diffuser is a pump accessory installed at the suction side of a centrifugal pump. It acts as a flow-conditioning device that removes turbulence and directs liquid into the pump with a uniform velocity profile. Additionally, it incorporates a built-in strainer to capture particles and protect pump internals.

In short: its part strainer, part flow-straightener, and part elbow – all rolled into one compact unit.

A suction diffuser is important because it protects pumps, improves efficiency and saves installation space. Instead of using a separate strainer, long suction piping, and additional fittings, the suction diffuser combines all these functions into one compact unit. A suction diffuser is not just an accessory — it’s an essential component that ensures long-term pump efficiency and protection.

Here’s why it’s so important:

A strainer and a suction diffuser might look like they do the same job, but they’re not the same thing. A strainer is a simple device — its only job is to filter out debris and protect equipment downstream. It doesn’t care how the fluid flows after passing through it.

A suction diffuser, on the other hand, is a smarter, multi-function device. Yes, it has a built-in strainer to catch debris, but it also includes flow-straightening vanes that align the liquid entering the pump. This prevents turbulence and ensures the pump receives smooth, uniform flow. On top of that, a suction diffuser is designed in an elbow-shaped body, meaning it can replace both the strainer and the required straight suction pipe length before the pump.

In simple words:

With three decades of expertise, we understand that downtime is costly. That’s why our suction diffusers are engineered for long service life, low maintenance, and reliable performance. Every product undergoes stringent testing to meet ASTM, ANSI, DIN, and EN standards, ensuring compatibility with global projects.

A suction diffuser isn’t just an accessory—it’s a necessity for protecting pumps, improving efficiency, and reducing system wear. At C-Way Engineering Exports, we deliver top-quality suction diffusers that meet the toughest industrial requirements.

Looking for a trusted suction diffuser manufacturer? Contact us today to get a customized quote for your project.

With decades of experience in the industry, 'C-Way Engineering Exports’ witnessed the critical importance of utilizing high-quality Pipes & Tubes that meet international standards. Whether you are in Oil and Gas, petrochemical, power generation, or any other industry relying on efficient and reliable piping systems, investing in high quality valves is essential.

Don't compromise on safety, performance, or longevity. Partner with trusted suppliers like us ‘C-Way Engineering Exports’, who prioritize quality and adherence to standards, ensuring your projects are built to last.

Contact us today to explore our full range of industrial valves, pipe fittings, pipes & tubes, flanges and experience the excellence of our products and how we can support your piping needs with our expertise and premium-grade valves. Let's build a robust infrastructure together.

We typically supply 20 mesh (standard duty) and 40 mesh (fine duty) strainers. The choice depends on the cleanliness of the fluid:

At rated flow, the pressure drop is usually between 0.05 to 0.15 bar (0.7–2 psi) depending on mesh size and fluid velocity. Buyers should consider this when calculating pump head to avoid system inefficiency.

While suction diffusers are not governed by a single global standard, they are designed and tested in line with:

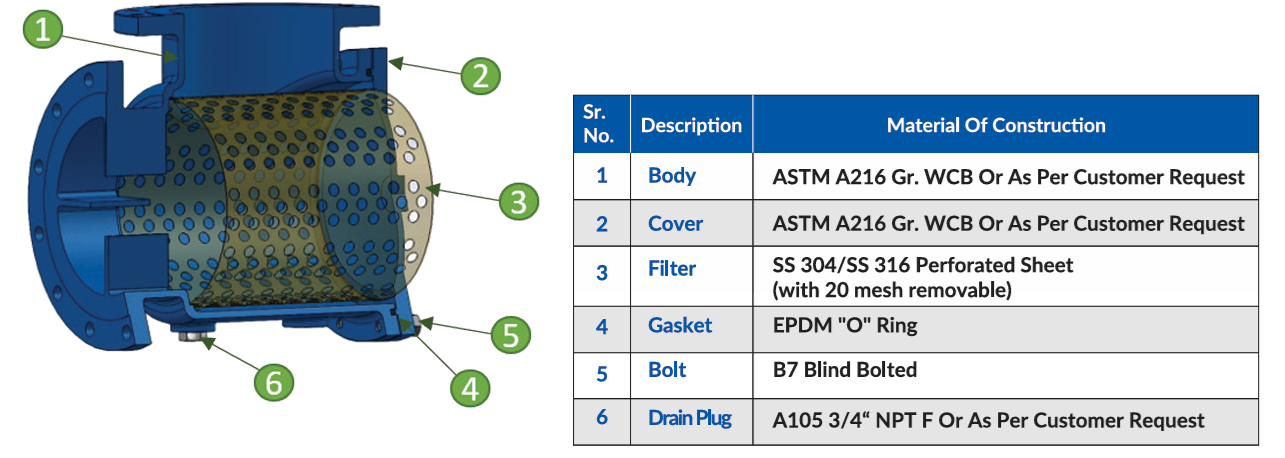

Our Standard suction diffusers are manufactured with:

Yes. Material selection is the key here:

Maintenance has been simplified in our design:

Yes. A suction diffuser acts as a strainer + flow straightener + elbow in one unit. Its built-in vanes condition the flow, replacing up to 10 diameters of straight suction piping.