ASME B16.47 Flanges: A Complete Guide for Large Diameter Piping Systems

In large-scale industrial piping systems, where reliability and strength are critical, ASME B16.47 flanges play a vital role. These flanges are specifically designed for large diameter pipes (NPS 26 to NPS 60) used in oil & gas, petrochemical, power generation, and water transmission projects.

ASME B16.47 defines the dimensions, tolerances, pressure classes, and materials for large diameter steel flanges, ensuring safety, compatibility, and standardization across industries worldwide. Understanding the key aspects of ASME B16.47 is essential when specifying or sourcing flanges for large piping networks.

What Is ASME B16.47?

ASME B16.47 is an American Society of Mechanical Engineers (ASME) standard that governs large diameter steel flanges ranging from NPS 26 to NPS 60.

Before the introduction of ASME B16.47, the widely used ASME B16.5 covered flanges only up to NPS 24. As industrial demands grew, especially in oil refineries, power plants, and offshore platforms, larger diameter pipelines became common—creating the need for standardized flanges in higher sizes.

The ASME B16.47 standard ensures interchangeability, safety, and uniform design for such large flanges, offering consistent pressure ratings and material compatibility.

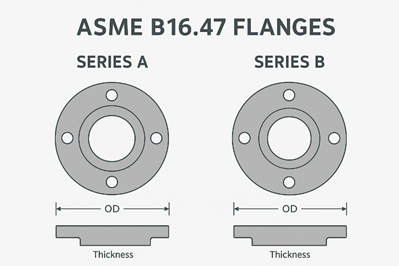

ASME B16.47 Series A vs Series B Flanges

ASME B16.47 is divided into two series: Series A and Series B. Both have different dimensional and design characteristics. The main distinction lies in bolt hole spacing, flange thickness, and overall load-bearing capacity.

| Feature | Series A (formerly MSS SP-44) | Series B (formerly API 605) |

| Application | Heavier, used in high-pressure, high-stress conditions | Lighter, used in less critical applications |

| Bolt Circle Diameter | Larger | Smaller |

| Flange Thickness | Thicker and heavier | Thinner and lighter |

| Number of Bolts | Fewer but larger bolts | More bolts, smaller in size |

| Typical Industries | Oil & Gas, Offshore, Power Generation | Water Transmission, General Industries |

ASME B16.47 Series A flanges are designed for rigidity and high-pressure conditions, while Series B flanges are suited for less critical or weight-sensitive systems.

In terms of cost, Series A flanges are more expensive due to their thicker cross-section and higher pressure handling, whereas ASME B16.47 Series B flanges offer a more economical alternative for moderate conditions. Both are standardized for pressure classes 150, 300, 400, 600, and 900.

What Are ASME B16.47 Series A and B Flanges in Short?

In simple terms —

- Series A = Stronger, heavier, high-pressure applications

- Series B = Lighter, economical, low to medium-pressure service

Choosing between them depends on your project’s pressure requirements, space constraints, and cost considerations.

Types of ASME B16.47 Flanges

Although ASME B16.47 focuses on large diameter flanges, it primarily includes the following types:

- Weld Neck Flanges (WN):

- Designed for high-pressure and high-temperature service.

- Offers smooth stress distribution through the neck.

- Commonly used in refineries and power stations.

- Blind Flanges (BL):

- Used to seal the end of a pipeline, vessel, or pressure opening.

- Essential for inspection and maintenance sections.

Some manufacturers may also produce custom Slip-On flanges or Lap Joint flanges in B16.47 dimensions for non-critical service, but Weld Neck and Blind remain the standard.

Size Range and Pressure Classes

Pressure Ratings for ASME B16.47 Flanges

Pressure ratings represent the maximum allowable pressure at a specific temperature.

- Series A flanges handle higher pressure and stress, ideal for critical oil & gas systems.

- Series B flanges are optimized for moderate pressure pipelines where cost and weight efficiency are key.

ASME B16.47 flanges are available in Nominal Pipe Sizes (NPS) from 26 to 60 inches and are standardized under the following pressure classes:

- Class 150

- Class 300

- Class 400

- Class 600

- Class 900

The pressure rating defines the maximum pressure the flange can withstand at a given temperature. Higher pressure classes feature thicker, heavier flanges with larger bolt patterns.

Materials Used for ASME B16.47 Flanges

Material selection is a crucial factor influencing the performance, durability, and corrosion resistance of flanges. Common materials include:

| Material Type | Typical Grades | Applications |

| Carbon Steel | ASTM A105, A350 LF2 | General-purpose use, oil & gas pipelines |

| Stainless Steel | ASTM A182 F304, F316, F321 | Corrosive environments, chemical & marine industries |

| Alloy Steel | ASTM A182 F11, F22, F91 | High-temperature and high-pressure systems |

| Duplex & Super Duplex | F51, F53, F55 | Offshore and desalination plants |

| Nickel Alloy | Inconel 625, Hastelloy C276 | Extreme chemical resistance |

Choosing the right material depends on operating conditions, temperature, pressure, and fluid composition.

Applications of ASME B16.47 Flanges

These flanges are widely used in large-scale industrial systems where durability and sealing integrity are vital. Major applications include:

- Oil & Gas – Transmission lines, manifolds, offshore platforms.

- Power Generation – Steam and cooling systems.

- Petrochemical – Process plants, reactors, and exchangers.

- Water Treatment – Intake and discharge pipelines.

- Marine & Shipbuilding – Seawater handling systems.

- Mining – Slurry and tailing transport systems.

These flanges provide leak-proof connections and long-term durability under severe operating conditions.

Advantages of ASME B16.47 Flanges

- Standardization: Global compatibility ensures easy interchangeability in large pipeline projects.

- High Strength: Designed to handle extreme pressure and temperature conditions.

- Leak Prevention: Weld neck design ensures tight, reliable joints.

- Versatility: Suitable for multiple materials and pressure classes.

- Enhanced Safety: Rigid design reduces the risk of flange failure in high-stress applications.

- Ease of Maintenance: Blind flanges enable convenient inspection and isolation.

Dimensional Overview

Key dimensional parameters defined in ASME B16.47 include:

- Outside diameter of flange (OD)

- Bolt circle diameter (BCD)

- Number and size of bolt holes

- Hub dimensions (for weld neck type)

- Raised face or ring-type joint (RTJ) details

Engineers must ensure dimensional compatibility between mating flanges and gaskets according to the selected pressure class.

Quality and Inspection Standards

Flanges manufactured under ASME B16.47 typically undergo:

- Ultrasonic and Radiographic Testing (UT / RT)

- Visual and Dimensional Inspection

- Hydrostatic and Pressure Testing

- Material Certification (EN 10204 3.1 or 3.2)

These checks ensure the flanges meet both mechanical and metallurgical properties required for critical service applications.

How to Select ASME B16.47 Flange for a 24-Inch Pipe?

When choosing the right ASME B16.47 flange for a 24-inch or larger pipe, consider:

- Pressure & Temperature: Match the flange pressure class (150–900) with your system’s requirements.

- Material: Select carbon steel for general use, stainless or duplex for corrosive service, and alloy steel for high-temperature environments.

- Series Type: Choose Series A for strength and rigidity or Series B for cost and weight efficiency.

- Facing Type: Decide between Raised Face (RF) or Ring Type Joint (RTJ) depending on sealing needs.

- Dimensional Compatibility: Verify measurements using the ASME B16.47 dimensions and weights table.

The ASME B16.47 flange standard provides a unified global guideline for large diameter flanges, ensuring safety, reliability, and interchangeability across major industries. Whether used in oil & gas pipelines, power plants, or water networks, these flanges guarantee performance and compliance under demanding operating conditions.

Choosing the right Series (A or B), material, and pressure class is essential to achieving long-term reliability in large pipeline systems.

If your project involves large diameter piping systems, sourcing ASME B16.47 flanges from a trusted and certified industrial flange manufacturer ensures consistent quality, dimensional accuracy, and superior performance.

Looking for reliable ASME B16.47 flanges for your next project?

Contact C-Way Engineering Exports today to discuss your requirements and receive our best factory prices within 24 hours from our sales team.