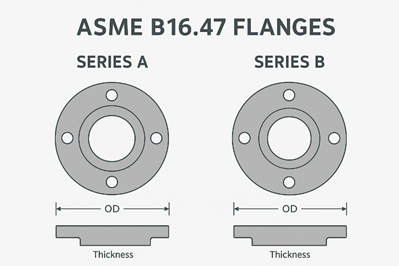

ASME B16.47 Series A vs Series B Flanges: Engineering Differences, Weight Impact & Cost Implications

Why Series Selection Matters in Large-Diameter Pipelines

In large diameter pipeline systems, selecting the correct flange series is not just a specification formality- it is a critical engineering decision that directly impacts structural integrity, installation feasibility, project cost, and long-term reliability.

ASME B16.47 provides two flange design options – Series A and Series B address different mechanical and economic requirements. However, improper selection between these two series often leads to over-engineering, unnecessary cost escalation, handling challenges, or installation delays.

This article focuses exclusively on the difference between ASME B16.47 Series A and Series B flanges in engineering design, weight, and also cost implications while choosing ASME B16.47 Series A vs Series B Flanges.

Where Series A and Series B Fit in ASME B16.47

ASME B16.47 applies to large diameter steel flanges from NPS 26 to NPS 60, primarily weld neck flanges and blind flanges, across pressure classes 150 through 900.

- Series A originates from MSS SP-44

- Series B originates from API 605

While both comply with ASME B16.47 requirements, they differ significantly in design philosophy, mechanical strength, weight, and cost, making series selection application-specific rather than interchangeable.

Engineering Design Differences Between ASME B16.47 Series A and Series B

Flanges Thickness and Structural Rigidity

Series A flanges are thicker and heavier, providing greater rigidity and resistance to bending under internal pressure and external loads. This increased thickness reduces flange rotation, especially in high-pressure or cyclic loading conditions.

Series B flanges are thinner, offering adequate performance for moderate pressure systems but with lower structural stiffness compared to Series A.

Engineering Impact:

- Series A → Better resistance to flange deformation

- Series B → Suitable where mechanical loads are lower

Bolt Pattern and Load Distribution

One of the most critical engineering differences lies in the bolt configuration:

- Series A: Fewer but larger-diameter bolts

- Series B: More bolts but smaller in diameter

Series A bolts generate higher individual clamping force, resulting in better gasket seating stress and improved sealing reliability under high pressure.

Series B distributes load across more bolts but with reduced individual bolt force, which is adequate for lower pressure services.

Engineering Impact:

- Series A → Superior sealing performance in critical services

- Series B → Adequate sealing with cost and weight benefits

Hub Geometry and Stress Transition

Series A weld neck flanges typically have a longer and thicker hub, allowing smoother stress transition from pipe to flange. This improves fatigue resistance, especially in pipelines subject to vibration or thermal cycling.

Series B hubs are shorter and lighter, which is acceptable for steady-state systems but less forgiving under fluctuating loads.

Weight Impact: How Series Selection Affects Handling and Installation

Typical Weight Differences

For the same nominal size and pressure class, Series A flanges can weigh 15–30% more than Series B flanges. This weight difference increases significantly as pipe size grows beyond 36”, 48”, and 60”.

Impact Areas:

- Crane and lifting capacity

- Transportation cost

- Installation manpower

- Site safety planning

Installation Challenges in Large Diameters

In large-diameter sizes:

- Heavier Series A flanges require larger cranes and reinforced rigging

- Alignment during installation becomes more difficult

- Bolt tightening requires higher torque control

In contrast, Series B flanges offer:

- Easier handling

- Faster installation

Lower safety risk in elevated or offshore locations

Cost Implications of ASME B16.47 Series A vs Series B Flanges

Material Consumption and Forging Cost

Series A flanges consume more raw material due to thicker cross-sections. Larger forgings also require:

- Higher forging loads

- Longer heat treatment cycles

- Increased rejection risk

This directly increases manufacturing cost.

Machining, Drilling, and Bolting Cost

- Series A: Larger bolt holes, thicker machining sections

- Series B: More bolt holes, but less machining depth

Overall, Series A machining cost is typically higher due to material volume and tool wear.

Transportation and Logistics Cost

Freight charges for large flanges are primarily weight-based.

A project using Series A flanges may incur:

- Higher shipping cost

- Specialized packing

- Additional handling equipment

Lifecycle Cost Consideration

While Series A flanges cost more initially, they often:

- Reduce maintenance frequency

- Minimize leakage risk

- Offer better long-term reliability in harsh environments

Series B flanges reduce upfront cost but may not be suitable for severe service conditions.

Application-Based Engineering Selection Guide: ASME B16.47 Series A vs Series B Flanges

When Series A Is Technically Justified

- High-pressure oil & gas transmission lines

- Offshore platforms and subsea manifolds

- Cyclic pressure and temperature service

- Critical hydrocarbon containment systems

When Series B Is the Smarter Choice

- Water transmission pipelines

- Cooling water systems

- Weight-restricted pipe racks

- Budget-sensitive EPC projects

- Non-critical service applications

Size-Specific Considerations

As diameter increases, engineering consequences are amplified:

- 36” → Series B often sufficient for cooling water and utilities

- 48” → Series choice depends heavily on pressure and material

- 60”+ → Weight, material strength, and lifting feasibility dominate decisions

In many large sizes, using high-strength duplex materials ASME B16.47 with Series B can achieve the required performance while controlling weight.

Material Interaction with Series A and Series B

Carbon Steel vs Stainless Steel

- Carbon steel increases weight rapidly in Series A

- Stainless steel improves corrosion resistance but increases cost

Duplex and Super Duplex Advantages

Duplex materials offer:

- Higher strength-to-weight ratio

- Ability to use thinner sections

- Improved corrosion resistance

In many offshore applications, Series B + Duplex can outperform Series A carbon steel designs.

Alloy and Nickel Alloys

Used in extreme environments:

- High temperature

- Sour service

- Aggressive chemicals

Cost is high but justified where failure risk is unacceptable.

Common Engineering and Procurement Mistakes

- Selecting Series A “just to be safe”

- Ignoring installation and lifting constraints

- Over-specifying pressure class

- Not coordinating with gasket and bolting design

- Mixing Series A and Series B without compatibility checks

ASME B16.47 Series A vs Series B Flanges at a Glance

| Criteria | Series A | Series B |

| Pressure | High | Low–Medium |

| Weight | Heavy | Lighter |

| Cost | Higher | Lower |

| Installation | Complex | Easier |

| Best For | Critical service | Utility service |

How You Can Optimize Cost Without Compromising Safety

- Perform early engineering review

- Match material strength with series selection

- Avoid default over-specification

- Work with experienced manufacturers during the design stage

Advantages of C-Way Engineering Exports

At C-Way Engineering Exports, we assist clients with:

- Engineering-driven series selection

- Material optimization for large diameters

- Custom forging feasibility

- Compliance with ASME B16.47 Series A & B

- Global project documentation and certification

FAQ

- Is Series A always stronger than Series B?

Yes, but strength may exceed actual system requirements. - Can Series B be used in oil & gas pipelines?

Yes, for low-pressure or non-critical services. - How much heavier is Series A?

Typically 15–30% heavier depending on size and class. - Does series selection affect gasket choice?

Yes, bolt load and seating stress differ. - Can Series A and Series B be mixed?

Only with careful compatibility verification.

Engineering-Driven Series Selection Is the Key

Choosing between ASME B16.47 Series A and Series B flanges should never be a default decision. Weight, cost, installation constraints, and operating conditions must be evaluated together.

An engineering-driven selection approach ensures safety, optimizes cost, and improves long-term pipeline reliability.

Need expert guidance in selecting ASME B16.47 Series A or Series B flanges for your large-diameter piping project?

C-Way Engineering Exports offers engineering consultation, certified materials, and precision manufacturing for global oil & gas, power, water, and projects.

Contact us today to discuss your technical requirements and receive a tailored flange solution.