Ball Valve Failure Analysis: Why a Chemical Plant Replaced Their Previous Supplier

In chemical processing plants, valve reliability is directly linked to plant safety, uptime, and operating cost. Even a minor leakage from a process valve can lead to product loss, safety hazards, environmental concerns, and unplanned shutdowns. Despite this, many chemical plants still face recurring valve failures, often not because of extreme operating conditions, but due to incorrect valve selection and poor application engineering.

This case study explains how a mid-sized chemical processing plant handling acids, alkalis, and solvents experienced repeated ball valve failures and ultimately replaced their previous supplier. The study is based on a realistic failure analysis approach, reflecting common challenges seen across chemical plants in the USA, Europe, Africa and the Middle East.

C-Way Engineering Exports was involved after multiple maintenance cycles failed to resolve the issue. The solution was not a temporary repair, but a fundamental engineering correction.

Client Feedback from the Project

Before diving into the technical failure analysis, here is what the project stakeholders had to say about their experience working with C-Way Engineering Exports:

“C-Way Engineering Exports supported our project with timely communication, technical clarity, and consistent valve quality. The SS316 3-piece ball valves supplied met both ANSI and DIN requirements and performed as expected in chemical service.”

— Mark Reynolds, Project Engineer, EPC Contractor

“Beyond product quality, what impressed us most was the technical support and follow-up from C-Way Engineering Exports. Their team remained available even after installation to ensure smooth operation. This level of support builds long-term trust.”

— Ahmed Al-Hassan, Plant Operations Manager

Project Background: Chemical Process and Operating Conditions

The plant operates continuous chemical processing lines involving corrosive acids, alkaline solutions, and organic solvents. The ball valves in question were installed on process lines used for:

- Chemical transfer between reactors

- Isolation of dosing lines

- Process shutdown and maintenance isolation

Operating Parameters

- Pipe sizes: DN50 to DN150

- Pressure rating: ANSI Class 150 / DIN PN16

- Operating temperature: Ambient to moderate elevated temperatures

- Media: Acidic and alkaline chemicals, mixed solvents

- Duty: Frequent operation with regular maintenance requirements

The valves were critical to daily plant operations, and any failure immediately affected production continuity.

The Problem: Repeated Ball Valve Failures in Chemical Service

Within a short operating period, the plant experienced recurring failures of ball valves supplied by their previous vendor. Maintenance teams initially treated these as isolated incidents, but over time a clear pattern emerged.

Observed Failures

- External leakage from body joints after a few months of service

- Internal leakage across the ball and seats, causing poor shut-off

- Stem leakage, especially during frequent operation

- Corrosion marks and pitting on internal components

- Valves becoming hard to operate or seized

In several cases, valves had to be replaced every 3–6 months, resulting in frequent shutdowns and safety concerns for operators handling hazardous chemicals

Operational Impact on the Chemical Plant

The valve failures had a direct and measurable impact:

- Increased maintenance frequency

- Unplanned production downtime

- Higher spare inventory cost

- Safety risk during valve removal

- Loss of confidence in valve reliability

From a procurement and maintenance standpoint, it became clear that replacing failed valves repeatedly was not a sustainable solution

Root Cause Analysis: Why the Ball Valves Were Failing

C-Way Engineering Exports conducted a failure analysis in collaboration with the plant’s maintenance and engineering teams. The analysis focused on valve construction, material selection, and service compatibility.

Key Root Causes Identified

| Observed Issue | Engineering Root Cause |

| Body joint leakage | Two-piece ball valve design with limited sealing integrity |

| Internal leakage | Low-grade PTFE seats unsuitable for chemical media |

| Corrosion on internals | Use of SS304 instead of SS316 |

| Stem leakage | Inadequate packing material |

| Short service life | No application-specific valve selection |

Incorrect Material Selection

The previous supplier provided generic stainless steel ball valves, primarily focusing on cost. In several cases, SS304 was used instead of SS316 / SS316L, offering insufficient resistance to chemical corrosion.

Inappropriate Valve Design

The valves were predominantly 2-piece ball valves, which:

- Required complete removal from the pipeline for maintenance

- Increased handling risk during servicing

- Accelerated wear due to frequent disassembly

Lack of Application Engineering

Most critically, the valves were supplied without proper evaluation of chemical compatibility, seat material suitability, or long-term maintenance requirements.

Why the Previous Supply Approach Was Ineffective

The issue was not related to a single defective batch, but rather a systemic supply approach that lacked application engineering. The earlier supplier treated the requirement as a product transaction instead of an engineered solution for chemical service.

Common shortcomings included:

- No detailed media compatibility evaluation

- No discussion around maintenance frequency and access

- No lifecycle cost or downtime impact analysis

- Inconsistent quality across supplied batches

- Limited technical support after installation

This approach is unfortunately common in chemical industry projects, where initial price is prioritized over long-term performance and reliability.

Engineering Solution by C-Way Engineering Exports

After detailed analysis, C-Way Engineering Exports recommended a complete change in valve design and material specification, rather than minor modifications.

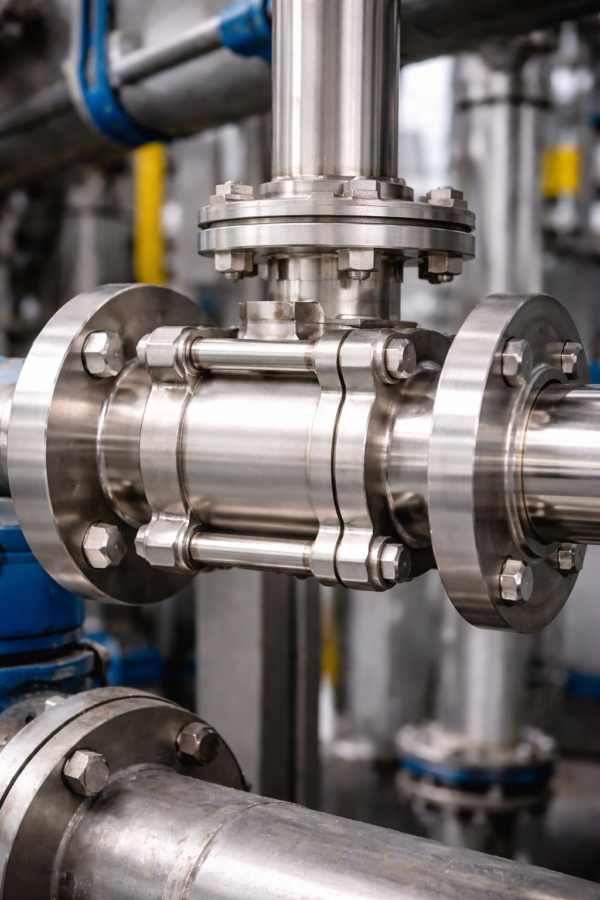

Recommended Valve Configuration

| Component | Specification |

| Valve Type | 3-Piece Ball Valve |

| Body Material | SS316 / SS316L |

| Ball | SS316, mirror polished |

| Seats | PTFE / Reinforced PTFE |

| Stem | SS316 |

| Packing | PTFE |

| Gaskets | PTFE |

| End Connections | Flanged (ANSI / DIN) |

| Pressure Rating | Class 150 / PN16 |

Why SS316 PTFE Seated 3-Piece Ball Valves Are Ideal for Chemical Plants

- Superior Corrosion Resistance

SS316 / SS316L provides excellent resistance to acids, alkalis, and solvents due to its molybdenum content, making it the preferred choice for chemical service worldwide.

- Chemical Compatibility of PTFE

PTFE seats and seals are chemically inert and suitable for a wide range of aggressive media, ensuring long-term sealing performance.

- Inline Maintenance Advantage

The 3-piece ball valve design allows the center body to be removed without disturbing the pipeline, reducing downtime and improving maintenance safety.

- Compliance with Global Standards

The valves were manufactured to meet:

- ANSI / ASME requirements for the USA

- DIN / EN standards for Europe

- Project specifications common in the Middle East

Installation and Commissioning

The replacement valves were installed during a planned shutdown. C-Way Engineering Exports provided:

- Installation guidance

- Torque recommendations

- Pre-dispatch hydrostatic and leakage testing

- Material traceability documentation

Commissioning was completed without complications.

Performance Results: Before vs After Comparison

| Parameter | Previous Valves | C-Way Valves |

| Leakage incidents | Frequent | None observed |

| Maintenance frequency | Every 3–6 months | Significantly reduced |

| Downtime | High | Minimal |

| Operator safety | Compromised | Improved |

| Service life | Short | Long-term reliability |

After several months of operation, the plant reported zero leakage incidents and stable valve performance.

This case study highlights several important factors:

- Chemical service requires application-specific valve selection

- Material compatibility is critical for long-term reliability

- 3-piece ball valves significantly reduce maintenance downtime

- Lowest price often results in highest lifecycle cost

- Working with an engineering-focused manufacturer makes a difference

Why Chemical Plants Choose C-Way Engineering Exports

C-Way Engineering Exports is an experienced industrial ball valve manufacturer and exporter, supplying reliable valve solutions to chemical plants, EPC contractors, and OEMs across the USA, Europe, Africa and the Middle East.

Our approach focuses on:

- Application engineering, not just product supply

- Material traceability and testing

- Compliance with international standards

- Consistent manufacturing quality

- Long-term customer support

FAQ

1. Why do ball valves fail in chemical plants?

Ball valves fail primarily due to incorrect material selection, unsuitable seat materials, and designs not intended for frequent maintenance or corrosive media.

2. Which ball valve material is best for acid and alkali service?

SS316 / SS316L stainless steel combined with PTFE seats is widely used for handling acids, alkalis, and solvents in chemical plants.

3. Why are 3-piece ball valves preferred in chemical industries?

3-piece ball valves allow inline maintenance, reduce downtime, and improve safety when servicing valves handling hazardous chemicals.

4. Are PTFE seats suitable for chemical applications?

Yes. PTFE is chemically inert and suitable for a wide range of aggressive chemical media, making it ideal for chemical process valves.

5. Can the same valve be used for ANSI and DIN systems?

Yes. Ball valves can be manufactured to comply with ANSI Class 150 / 300 and

DIN PN16 / PN40, depending on project requirements.

6. How does proper valve selection reduce maintenance cost?

Correct valve design and material selection reduce leakage, extend service life, minimize downtime, and lower overall lifecycle cost.

Conclusion

This case study demonstrates that ball valve failure in chemical plants is rarely accidental. It is usually the result of incorrect design and material selection, driven by cost-focused procurement rather than engineering evaluation.

By switching to SS316 PTFE seated 3-piece ball valves, the chemical plant achieved reliable operation, reduced maintenance, and improved safety, proving that the right valve selection is an investment, not an expense.

Need Engineering Support?

Facing repeated ball valve failures in chemical service?

Share your media, pressure, temperature, and standard requirements, and the engineering team at C-Way Engineering Exports will help you select the right valve for long-term reliability.