A municipal contractor from Chile contacted C-Way Engineering Exports after facing significant leakage and operational failures caused by aging valves in their municipal water distribution and wastewater network. The existing valves-installed more than 15 years earlier-were leaking heavily, causing pressure drops, constant maintenance interruptions, and high levels of water loss. After a detailed engineering evaluation of pipeline conditions, operating pressures, fluid characteristics, and visual inspection through photos and video calls, the project engineer recommended replacing the deteriorated valves with modern EPDM-lined butterfly valves.

The chosen EPDM-lined butterfly valves offered superior corrosion resistance, leak-tight performance, and long-term reliability under Chilean water conditions. Once installed, the municipal contractor reported complete leakage elimination, stable pressure management, and improved distribution efficiency across the water network. This case study demonstrates how advanced valve technology delivered a durable, cost-effective solution for a critical municipal application.

About the Client – Chilean Municipal Contractor

The client is a well-established municipal contractor responsible for maintaining water distribution pipelines, wastewater conveyance systems, and pumping stations serving several regions in Chile. Their responsibilities include pipeline repair, valve maintenance, water quality assurance, and ensuring uninterrupted flow for thousands of residential and industrial users. Due to aging infrastructure and increasing operational demands, the contractor faced recurring challenges with leaking valves, pressure fluctuations, and rising non-revenue water (NRW).

The contractor contacted C-Way Engineering Exports after repeated shutdowns and leak incidents involving outdated gate valves and butterfly valves that no longer sealed properly. Their engineering team needed a dependable, corrosion-resistant valve replacement that could withstand Chile’s varying water chemistry, high cycling frequency, and municipal operating pressures. C-Way Engineering Exports was selected to provide a complete solution due to its global reputation as a reliable industrial valve manufacturer and butterfly valve exporter.

Water Network Challenges in Chile

Chile’s municipal water systems face several infrastructure challenges primarily driven by aging pipelines, fluctuating water quality, and the geographical diversity spanning coastal, mountainous, and desert regions. Many water distribution lines were installed decades ago and continue to operate with limited modernization. As a result, valve leakage, pipe corrosion, and pressure instability are common across municipalities.

One of the most pressing issues is Chile’s increasing water scarcity, especially in central and northern regions. Non-revenue water caused by leaks, aging valves, and inefficient flow control leads to significant waste. In some areas, NRW levels can exceed 30%, putting additional pressure on municipal authorities to improve operational efficiency. Additionally, wastewater networks often handle variable fluid compositions, leading to corrosion and wear on internal valve components. This contractor’s system was no exception, with several pipeline sections suffering from reduced pressure, water loss, sediment build-up, and continuous leakage at the valve points.

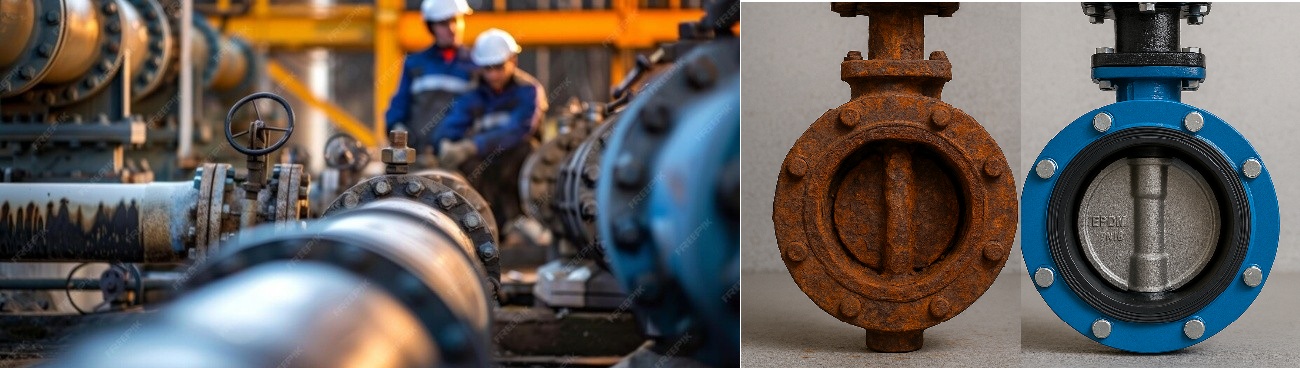

The Problem – Aged & Leaking Valves

When the municipal contractor contacted C-Way Engineering, they reported that several valve installations had reached end-of-life conditions. The existing valves—mainly older ductile iron butterfly valves and cast iron gate valves—showed multiple issues:

• Severe leakage even in fully closed positions

• Worn-out rubber seats causing internal bypass

• Corroded valve discs and bodies due to long-term water exposure

• High operating torque, making manual operation difficult

• Sediment accumulation, which damaged the closure mechanism

• Frequent maintenance, increasing operational cost

• Inconsistent pressure across water distribution zones

These conditions contributed to noticeable pressure drops and unplanned shutdowns during peak supply hours. Certain valves were no longer providing isolation when needed, disrupting repair work and delaying maintenance. Water loss due to leakage significantly increased operational costs, intensifying the urgency of replacing the aging valve installations.

The contractor needed a modern, reliable valve solution capable of providing leak-tight shutoff, long service life, and corrosion resistance under Chilean water and wastewater conditions.

Engineering Assessment

C-Way Engineering’s technical team conducted a thorough evaluation of the contractor’s system through video call discussions, pipeline layout drawings, valve condition photographs, and operational pressure data. Our engineers analyzed the root cause of leakage, which was primarily due to worn seats, corroded metal components, and outdated material specifications that were not suitable for long-term municipal service.

We assessed several critical parameters:

• Operating pressure of PN10–PN16

• Water chemistry and presence of chlorination

• Sediment load in wastewater lines

• Pipeline connection standards

• Space constraints for installation

• Required torque and operability

Based on this evaluation, we recommended modern EPDM-lined ductile iron butterfly valves as the most suitable replacement solution. These valves offer exceptional sealing performance, corrosion resistance, and easy operation—ideal for municipal water and wastewater systems in Chile.

Why EPDM-Lined Butterfly Valves Were Chosen

EPDM-lined butterfly valves were selected due to their superior performance under municipal operating conditions. Several technical advantages justified this choice:

1. Leak-Tight Shutoff

EPDM rubber provides a flexible, durable sealing interface, ensuring zero leakage even under high cycling conditions.

2. Corrosion Resistance

The ductile iron body with fusion-bonded epoxy (FBE) coating combined with stainless-steel discs provides long-term protection against corrosion, meeting the requirements of Chile’s diverse water chemistry.

3. Easy Operation

EPDM-lined valves require significantly lower torque, reducing operator effort and improving safety.

4. Durable Material Selection

• DI body for strength

• CF8/CF8M stainless-steel disc

• High-performance EPDM seat

These materials ensure longevity and minimize maintenance.

5. Standards Compliance

The valves comply with key global standards including:

• EN 593

• ISO 5752

• API 609

• AWWA C504

This ensured seamless integration with the contractor’s existing water infrastructure.

6. Versatility

Suitable for potable water, wastewater, raw water, and treated water, making them ideal for multi-zone municipal application.

Given these advantages, the EPDM-lined butterfly valve emerged as the most effective solution for aging valve replacement in the municipal water network in Chile.

Product Specifications Supplied

C-Way Engineering supplied a complete batch of EPDM-lined ductile iron butterfly valves, configured specifically for the contractor’s technical requirements:

• Type: Wafer and Lug Type Butterfly Valves

• Sizes: DN100 to DN600

• Body Material: Ductile Iron (DI)

• Disc Material: SS304 / SS316

• Seat: High-grade EPDM rubber

• Pressure Class: PN10 and PN16

• Coating: Fusion Bonded Epoxy (minimum 250 microns)

• Standards: EN 593, ISO 5752, AWWA C504, API 609

• Testing: Hydrostatic test, seat leakage test, coating thickness test, torque test

These specifications ensured reliable sealing, corrosion resistance, and long service life.

Installation & Commissioning by Municipal Contractor

After receiving the valves, the municipal contractor carried out installation and commissioning at multiple locations within the water network. Their team reported:

• Proper pipeline preparation and cleaning

• Accurate flange alignment

• Bolt tightening per recommended torque values

• Smooth operation during opening and closing cycle tests

• No visible misalignment or seat deformation

• Zero leakage during hydrostatic commissioning

The installation team appreciated the quality of the valves, lightweight design and compact structure of the valves, which simplified retrofitting into existing pipelines. The EPDM seat enabled quick sealing without requiring high torque or external adjustments. Once operational, the valves immediately restored pressure stability and flow control across affected zones.

Results Achieved

The new EPDM-lined butterfly valves delivered outstanding performance improvements:

✔ Zero Leakage

All leakage issues caused by the old valves were completely eliminated.

✔ Improved Pressure Management

Stable distribution pressure was restored across the network, even during peak consumption.

✔ Reduced Maintenance Costs

Thanks to corrosion-resistant materials and a robust EPDM seat, maintenance frequency dropped significantly.

✔ Extended Valve Life

Expected lifespan increased by over 10–15 years compared to the older valves.

✔ Reduced Water Loss (NRW)

The contractor observed a measurable reduction in water loss due to the tight shutoff.

✔ Enhanced Network Reliability

Unplanned shutdowns and emergency repairs were reduced, improving service continuity for the community.

Our Client’s Testimonial

“We are extremely satisfied with the butterfly valves supplied by C-Way Engineering Exports. The build quality, coating uniformity, and overall finishing were far superior to what we received from our previous supplier. In the past, we faced 2–3 valves arriving with damaged bodies or poor seat alignment, which caused immediate installation delays. With C-Way’s valves, every unit arrived in perfect condition, properly tested, and ready for installation. The performance after commissioning has been exceptional, and we will continue sourcing from C-Way for future projects.”

— Carlos Muñoz, Operations Manager, Municipal Water & Wastewater Division (Chile)

“The EPDM-lined butterfly valves supplied by C-Way Engineering Exports solved our persistent leakage issues completely. The valves were easy to install, smooth to operate, and immediately restored pressure stability in our water network. We appreciate the technical support, fast response, and excellent product quality.”

— Javier Rojas, Maintenance Supervisor, Water Distribution Network

If your water or wastewater network is experiencing aging valves, leakage, or pressure issues, contact C-Way Engineering Exports for reliable EPDM-lined butterfly valves and complete flow-control solutions designed for municipal applications. As a trusted industrial valve manufacturer and butterfly valve exporter, we deliver durable, leak-tight, and cost-effective valve solutions worldwide.