Mining slurry systems in Africa face extreme challenges – abrasion, chemical attack, and constant pressure fluctuations. These factors make valves especially vulnerable, leading to frequent failures, downtime, and high maintenance costs.

Ball valves are a cornerstone of mining slurry pipelines, enabling precise flow control in highly demanding conditions. Yet, even the best valves can fail if their sealing system is not engineered for abrasive slurry. When seals leak, the impact is immediate: unplanned downtime, environmental hazards, lost production, and skyrocketing maintenance costs.

One of our African clients, a leading phosphate mining operation, recently approached us after experiencing recurring leakage in their existing ball valves. The problem wasn’t just costly—it was interrupting production schedules and creating safety risks for their operators.

This case study highlights how we solved the issue using advanced PTFE and metal-seated ball valve seals, extending service life and improving overall plant reliability.

The Client’s Challenge

The client was operating a slurry handling line in a phosphate mining plant. They had been relying on conventional soft-seated ball valves for years. However, within just a few months of service, the valves began showing signs of stem leakage.

Key issues identified:

• Stem leakage due to seal wear under abrasive slurry load.

• Frequent valve replacements, causing costly downtime.

• High maintenance costs from spare parts and emergency shutdowns.

• Safety concerns as leaking slurry was corrosive and could damage surrounding equipment.

The client wanted a long-term solution, not just another temporary repair.

Understanding Ball Valve Seal Failures in Mining Slurry Systems

Mining slurry lines carry highly abrasive fluids, often mixed with rock particles, fine solids, and chemical additives used for ore processing. While ball valves are generally robust, standard designs are not always suited for these conditions.

Common causes of ball valve seal failure in slurry systems include:

• Abrasive wear – Continuous contact with rock and mineral particles erodes PTFE and elastomer seats, eventually compromising sealing integrity.

• Pressure fluctuations and cycling – Frequent pump starts, stops, and pressure surges can deform soft valve seals, reducing their ability to maintain a tight shutoff.

• Chemical attack – Slurries often contain acidic or corrosive additives that can degrade unreinforced PTFE or elastomer materials.

• Operational strain – Repeated leakage results in frequent production interruptions, increased maintenance labor, and high replacement costs.

These factors combine to create high-risk conditions for Industrial valve failure, emphasizing the need for robust, specially engineered ball valves for mining slurry service.

Client Approach: Seeking a Reliable Slurry Valve Solution

Client’s primary goals were:

1. Eliminate leakage in high-solids slurry pipelines.

2. Improve valve reliability and operational longevity.

3. Reduce maintenance costs and unplanned downtime.

After reviewing multiple supplier options, the client approached our team to provide high-performance ball valves specifically designed to withstand abrasive and chemically aggressive slurry environments. They sought proven engineering solutions rather than off-the-shelf components that had previously failed under similar conditions.

Root Cause Analysis: Why Ball Valves Fail in Slurry Service?

Before recommending a solution, our engineering team conducted a comprehensive failure analysis. This included field inspections, material testing, operational data review, and process chemistry assessments. Key findings were:

1. Visual inspection – The PTFE seats in the existing valves displayed abrasion grooves and deformation, evidence of severe wear from solid-laden slurry.

2. Material evaluation – The original seals lacked reinforcement, reducing resistance to abrasive wear and chemical attack.

3. Operational review – Frequent pressure surges and pump start-stop cycles subjected the soft seats to extreme mechanical stress.

4. Process chemistry assessment – Acidic or chemically-laden slurries accelerated the degradation of PTFE, further compromising the sealing surface.

Conclusion: Standard soft-seated ball valves were simply not engineered for abrasive slurry service. To prevent repeated failures, a specialized solution with durable seat materials and optimized valve design was necessary.

Our Solution: PTFE & Metal-Seated Ball Valves for Slurry Applications

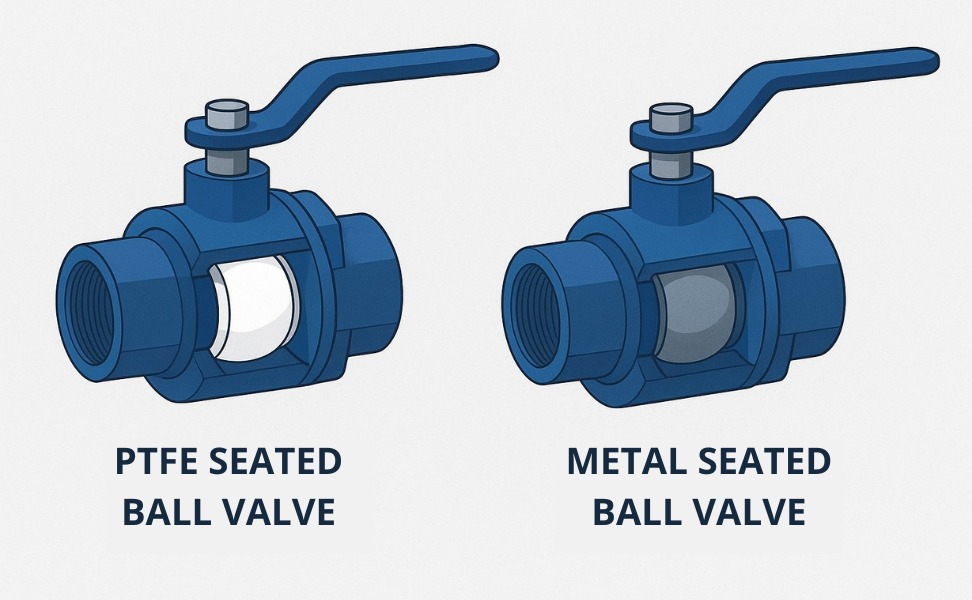

Based on the analysis, our team implemented a dual-strategy approach, selecting PTFE-seated valves for moderate slurry lines and metal-seated valves for highly abrasive or high-pressure lines.

Reinforced PTFE-Seated Ball Valves

PTFE ball valve, slurry service ball valve and chemical-resistant ball valve.

• Best for: Moderate slurry abrasiveness and chemically aggressive lines.

• Benefits:

o High chemical resistance to acids and additives.

o Smooth sealing performance, maintaining leak-free operation.

o Lower lifecycle cost compared to fully metal-seated designs.

Metal-Seated Ball Valves

Metal-seated ball valve, abrasion-resistant valve and mining slurry valve.

• Best for: Highly abrasive, high-pressure slurry lines.

• Benefits:

o Extreme durability against erosion and mechanical wear.

o Long-term seal integrity under high solids concentrations.

o High-temperature and high-pressure performance for critical pipelines.

Additionally, we provided installation guidance, including:

• Correct valve orientation to minimize seat stress.

• Soft-start procedures to reduce pressure shocks during commissioning.

• Periodic inspection recommendations to proactively detect wear before it affects performance.

Results: Reliable Operation and Zero Leakage

Six months after installation, the mining operation reported measurable improvements:

• Zero unplanned leakage events, eliminating slurry spillage and production interruptions.

• Extended valve service life – metal-seated valves lasted more than three times longer than prior PTFE valves.

• Reduced maintenance costs and labor hours, as fewer replacements were needed.

• Improved safety and environmental compliance, thanks to minimized spillage and predictable operation.

Proper valve selection and engineering support can dramatically improve operational reliability in abrasive slurry systems.

Why PTFE & Metal-Seated Ball Valves Work?

By adopting PTFE and metal-seated ball valves, the client achieved several key benefits:

1. Consistent sealing performance – Maintained leak-free operation across abrasive slurry pipelines.

2. Significant cost savings – Reduced replacement frequency and minimized downtime.

3. Operational flexibility – Different valve types allowed optimization for various slurry severities.

4. Predictable production output – Fewer interruptions and smooth pipeline operations.

5. Enhanced safety and environmental compliance – Reduced risk of spills and operator exposure.

Customer Testimonials

Mr. Daniel Ndlovu, Maintenance Superintendent, Phosphate Mining Plant (South Africa):

“We struggled for years with leaking ball valves, especially from the stem area. It was costing us time, money, and productivity. After switching to the PTFE and metal-seated valves recommended by C-Way Engineering, the difference has been remarkable. No leaks, smoother operation, and far less maintenance. This has been a game-changer for our plant.”

Mark Johnson, Senior Process Engineer, Gold Processing Plant:

“The reinforced PTFE ball valves were ideal for less abrasive slurry lines. Easy to maintain, excellent sealing performance, and long-lasting.”

Why Choose Our PTFE & Metal-Seated Ball Valves for Mining

Our abrasive slurry ball valves, high-performance slurry valve, metal ball valve and PTFE-lined valve are engineered specifically for abrasive and corrosive slurry service, offering:

• Durable PTFE and metal-seated designs for long-term reliability.

• Custom solutions for various slurry abrasiveness, pressure, and chemical conditions.

• Field-proven performance to reduce maintenance costs and downtime.

Is your mining operation struggling with ball valve seal failures in slurry systems?

At C-Way Engineering Exports, our experienced engineering team delivers customized, high-performance solutions tailored to your needs.

As a trusted mining valve supplier, we specialize in PTFE and metal-seated ball valves designed for:

• Abrasive slurry pipelines

• Chemical resistance in ore processing lines

• High-pressure and high-temperature applications

Contact us today to discuss your requirements and learn how our solutions can boost your plant’s reliability, minimize downtime, and maximize operational efficiency.