2-Piece vs 3-Piece Ball Valves: Design, Maintenance & Application Comparison

In industrial piping systems, ball valves are among the most widely used shut-off valves due to their tight sealing, quick operation, and long service life. However, when it comes to selecting the right design, one common question engineers and procurement teams face is:

Should we choose a 2-piece ball valve or a 3-piece ball valve?

At first glance, both valve types appear similar. Yet, from a design, maintenance, lifecycle cost, and application perspective, the difference between a 2-piece and a 3-piece ball valve can significantly impact plant reliability, downtime, and long-term operating cost.

As an experienced industrial ball valve manufacturer and exporter, C-Way Engineering Exports works closely with EPC contractors, OEMs, and plant engineers across USA, Europe, UK, Middle East, and Asia. This guide explains the real engineering differences not just textbook definitions, so you can make the right decision for your application.

Understanding Ball Valve Construction in Industrial Systems

Before comparing designs, it is important to understand how ball valves function in industrial service.

A ball valve controls flow using a rotating spherical ball with a drilled bore. When the bore aligns with the pipeline, flow is allowed; when rotated 90°, the flow is shut off. This simple mechanism provides:

- Bubble-tight shut-off

- Minimal pressure drop (especially in full bore designs)

- Fast quarter-turn operation

- Long service life with minimal wear

However, the way the valve body is constructed determines how easy it is to maintain, how much downtime it causes, and where it should be used.

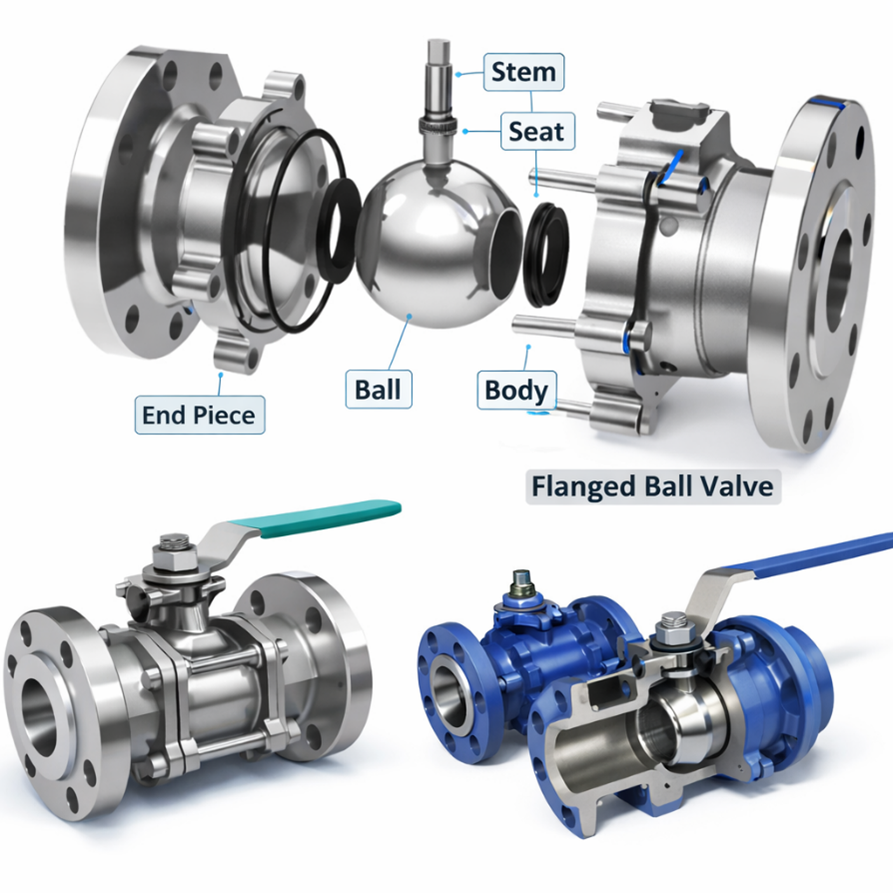

What Is a 2-Piece Ball Valve?

A 2-piece ball valve consists of two main body sections assembled together—typically one primary body and one end cap. The internal components (ball, stem, seats) are housed inside this assembled body.

Design Characteristics of 2-Piece Ball Valves

- Two body parts joined by threading or bolting

- Compact and rigid construction

- Floating ball design in most industrial sizes

- Fewer external joints compared to 3-piece valves

Common Materials Used

2-piece ball valves are widely available in:

- Stainless Steel Ball Valves (SS304, SS316)

- Carbon Steel Ball Valves (WCB, A105)

- Brass & Lead-Free Brass Ball Valves

- Forged Steel Ball Valves for high pressure

Typical End Connections

- Threaded (NPT / BSP)

- Flanged (ANSI Class 150 / 300, DIN PN16 / PN40)

Key Advantage of 2-Piece Ball Valves

The biggest advantage is lower initial cost and compact installation, making them suitable for general isolation duties where frequent maintenance is not expected.

What Is a 3-Piece Ball Valve?

A 3-piece ball valve is constructed using three separate components:

- One central body containing the ball and stem

- Two end caps connected to the pipeline

These three parts are bolted together, allowing the center section to be removed without disturbing the pipeline.

Design Characteristics of 3-Piece Ball Valves

- Modular, bolted construction

- Inline serviceability

- Floating ball design (standard)

- Designed for frequent maintenance and cleaning

Common Materials Used

3-piece ball valves are commonly supplied in:

- SS316 stainless steel ball valves (very common in chemical & food industries)

- Carbon steel and forged steel

- Duplex and Super Duplex stainless steel (corrosive service)

Typical End Connections

- Threaded

- Socket weld / butt weld

- Flanged ends

Key Advantage of 3-Piece Ball Valves

The biggest advantage is easy inline maintenance, which drastically reduces downtime, labor cost, and production loss.

2-Piece vs 3-Piece Ball Valves: Key Differences

| Parameter | 2-Piece Ball Valve | 3-Piece Ball Valve |

| Body Construction | Two-part body | Three-part modular body |

| Maintenance | Valve removal required | Inline maintenance possible |

| Downtime | Higher | Significantly lower |

| Initial Cost | Lower | Higher |

| Lifecycle Cost | Higher in long term | Lower over valve life |

| Installation Space | Compact | Slightly larger |

| Ideal Applications | General isolation | Maintenance-critical systems |

Maintenance & Downtime: The Real Differentiator

Maintenance Challenges with 2-Piece Ball Valves

In a 2-piece design:

- The valve must be fully removed from the pipeline for seat or seal replacement

- Flanges or threaded connections need to be dismantled

- Line shutdown time is longer

- Labor and re-alignment cost increases

For continuous process industries, this downtime can be more expensive than the valve itself.

Maintenance Benefits of 3-Piece Ball Valves

With a 3-piece ball valve:

- Only the center body is removed

- Pipeline remains intact

- Seats, seals, and ball can be replaced quickly

- Ideal for CIP/SIP and frequent cleaning

From a lifecycle perspective, 3-piece ball valves almost always offer better long-term value in critical services.

Pressure, Temperature & Standards Considerations

Pressure Ratings

Both 2-piece and 3-piece ball valves can be manufactured to:

- DIN PN10 / PN16 / PN25 / PN40

- ANSI Class 150 / 300 / 600

The pressure rating depends more on design thickness, material, and standard compliance than on the number of pieces alone.

Temperature Limitations

- Soft-seated ball valves (PTFE seats) are generally suitable up to 180–200°C

- High-temperature applications require:

- Reinforced seats

- Metal seated ball valves

- Cryogenic service requires special design and testing

Applicable Standards

Industrial ball valves are commonly manufactured to:

- ASME B16.34

- API 6D / ISO 17292

- DIN / EN standards

- API 607 / API 6FA fire safe requirements (when required)

Application-Based Selection Guide

Where 2-Piece Ball Valves Are Commonly Used

2-piece ball valves are ideal for:

- Water supply and distribution systems

- HVAC and chilled water lines

- General industrial isolation

- Non-critical utility services

They are widely selected where maintenance frequency is low and cost sensitivity is high.

Where 3-Piece Ball Valves Are the Better Choice

3-piece ball valves are strongly recommended for:

- Chemical and petrochemical plants

- Food & beverage processing

- Pharmaceutical and biotech facilities

- High-value or hazardous fluids

- Systems requiring frequent cleaning or inspection

In these industries, reduced downtime and easy maintenance outweigh higher initial cost.

Cost Comparison: Initial Price vs Long-Term Value

Many buyers initially select 2-piece ball valves because they appear cheaper. However, this approach often ignores total cost of ownership.

Hidden Costs to Consider

- Production loss during shutdown

- Maintenance labour

- Replacement frequency

- Safety risks during valve removal

In many industrial projects across USA, Europe, and Middle East, EPC contractors prefer 3-piece ball valves for critical lines because they reduce operational risk over the project lifecycle.

Common Buyer Mistakes When Choosing Ball Valves

From our manufacturing experience, common mistakes include:

- Selecting valves based only on unit price

- Ignoring maintenance access

- Not checking pressure-temperature limits

- Overlooking applicable standards

- Using utility-grade valves in process service

Avoiding these mistakes leads to better system reliability and lower long-term cost.

How to Choose the Right Ball Valve for Your Application

Before finalizing your selection, consider:

- Media type (water, chemical, gas, oil)

- Pressure class and operating temperature

- Frequency of operation and maintenance

- Applicable standards (DIN, ANSI, API)

- Budget vs lifecycle cost

An application-based approach always delivers better results than a price-based decision.

Why Choose C-Way Engineering Exports as Your Ball Valve Manufacturer?

C-Way Engineering Exports is a trusted industrial ball valve manufacturer and exporter, supplying valves to USA, Europe, UK, Middle East, Africa, and Asia.

Our strengths include:

- Engineering-driven valve selection support

- Wide range of DIN, ANSI, and API ball valves

- Stainless steel, carbon steel, and lead-free brass options

- Pressure, leakage, and fire-safe testing

- Export-ready packaging and documentation

We work closely with EPC contractors, OEMs, and distributors to ensure the right valve is supplied for the right application.

Both 2-piece and 3-piece ball valves have their place in industrial piping systems. The correct choice depends not on price alone, but on maintenance needs, downtime risk, and application criticality.

- Choose 2-piece ball valves for general isolation and utility services

Choose 3-piece ball valves for process lines, frequent maintenance, and critical applications

Frequently Asked Questions (FAQs)

- What is the main difference between 2-piece and 3-piece ball valves?

The main difference is related to body construction and maintenance access.

A 2-piece ball valve has a two-part body and generally needs to be removed from the pipeline for internal servicing. A 3-piece ball valve has a modular three-part design that allows the center body to be removed while keeping ANSI or DIN pipeline connections intact, reducing downtime during maintenance.

- Which ball valve is better for frequent maintenance in industrial plants?

A 3-piece ball valve is the preferred choice for applications that require frequent maintenance or cleaning, especially in chemical plants, refineries, and process industries. Its inline serviceability helps reduce shutdown time in ANSI Class 150 / 300 and DIN PN16 / PN40 systems commonly used across the USA, Europe, and the Middle East.

- Are 3-piece ball valves more expensive than 2-piece ball valves?

Yes, 3-piece ball valves typically have a higher initial price compared to 2-piece designs. However, for EPC projects and continuous process plants, they usually offer lower lifecycle cost due to faster maintenance, reduced labor, and minimal production loss over time.

- Can 2-piece and 3-piece ball valves handle the same pressure ratings?

Yes. Both 2-piece and 3-piece ball valves can be manufactured to meet similar pressure ratings, including ANSI Class 150 and Class 300, as well as DIN PN16 and PN40, depending on the valve design, material selection, and compliance with ASME, DIN, or EN standards.

- Are 3-piece ball valves suitable for API and fire-safe applications?

Yes. 3-piece ball valves can be designed and tested to meet API 607 or API 6FA fire-safe requirements, making them suitable for oil & gas and petrochemical applications where fire safety compliance is mandatory, particularly in the USA and Middle East markets.

- How do I choose between a 2-piece and 3-piece ball valve for my application?

The selection should be based on media type, operating pressure, temperature, maintenance frequency, downtime tolerance, and applicable standards such as ANSI, API, DIN, or EN.

For general isolation services, 2-piece ball valves are often sufficient, while 3-piece ball valves are recommended for critical, high-value, or maintenance-intensive applications.

Get Assistance

Need help selecting the right 2-piece or 3-piece ball valve for your project?

Share your media, size, pressure class, temperature, and standard requirement, and our engineering team at C-Way Engineering Exports will recommend the most suitable solution.