3-Way vs 4-Way Ball Valves: Design, Working Principle, and Industrial Applications

Why Multi-Port Ball Valves Are Critical in Industrial Piping

In industrial piping systems, flow control is rarely as simple as “open” or “close.” Modern plants like Process plants, OEM skids, and EPC projects demand flexibility-diverting flow between lines, mixing media, isolating equipment, or creating reliable bypass arrangements without excessive piping complexity. This is where multi port ball valves become critical.

This is where multi port ball valves-specifically 3 way ball valves and 4 way ball valves-become essential components.

3 way Ball Valve 4 Way ball valve

From more than three decades of hands-on experience in ball valve design, manufacturing, testing, and project execution for global markets, one reality is clear:

Multi-port ball valves are powerful engineering tools, but only when their internal design and working logic are fully understood.

Incorrect selection or misunderstanding of internal flow paths often leads to:

- Process upsets

- Commissioning delays

- Safety risks

- Costly rework during installation

Why Multi-Port Ball Valves Are Important?

In large industrial facilities, every additional pipe spool, tee, reducer, or flange joint increases:

- Pressure drop

- Leakage risk

- Installation time

- Maintenance complexity

Multi-port ball valves reduce piping complexity by integrating multiple flow paths into a single piece ball valve body. Instead of installing two piece ball valve or three isolation valves with fittings, a single multi-port valve can:

- Divert flow from one line to another

- Mix two streams into one

- Provide a compact bypass arrangement

- Simplify skid layouts

This article explains the three way vs four way ball valve decision from a practical engineering viewpoint—covering internal design, working principles, construction types, materials, standards, and real industrial applications.

What Is a Multi-Port Ball Valve?

A multi port ball valve is a quarter-turn valve in which the ball contains more than one internal flow passage, allowing controlled routing of fluid between three or four ports. These internal passages align with the valve body ports in different rotational positions, allowing controlled redirection or combination of flow.

Engineering Viewpoint

Unlike a standard 2-way ball valve (single inlet and outlet), a multi-port valve:

- Has three or four ports

- Uses L-shaped, T-shaped, or cross-drilled internal passages

- Enables diverting, mixing, or bypass functions

The most important principle you must understand is this:

The valve function is determined by the internal ball drilling, not merely by the number of ports on the valve body.

Difference from Standard Ball Valves

| Parameter | 2-Way Ball Valve | Multi-Port Ball Valve |

| Number of ports | 2 | 3 or 4 |

| Primary function | On / Off | Diverting, mixing, routing |

| Ball bore | Straight | L, T, or cross-drilled |

| Typical use | Isolation | Flow logic |

Multi-port valves are therefore functional control valves, not just isolation devices.

What Is a 3-Way Ball Valve?

A 3 way ball valve has three ports and is the most commonly used multi-port configuration in industrial piping systems. 90° (L-shaped body) and 180° inline with a side outlet (T-shaped body)

Typical Port Arrangement

- Two ports in line

- One port at 90 degrees

Internally, the ball is drilled in one of two configurations:

- L-port

- T-port

Understanding this distinction is critical for correct application.

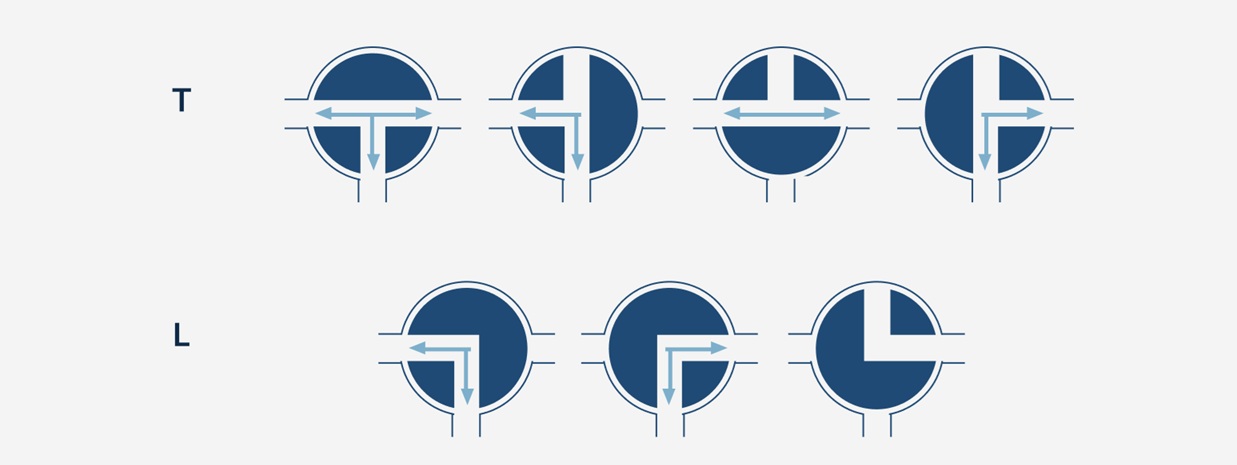

L-Port vs T-Port Ball Valve

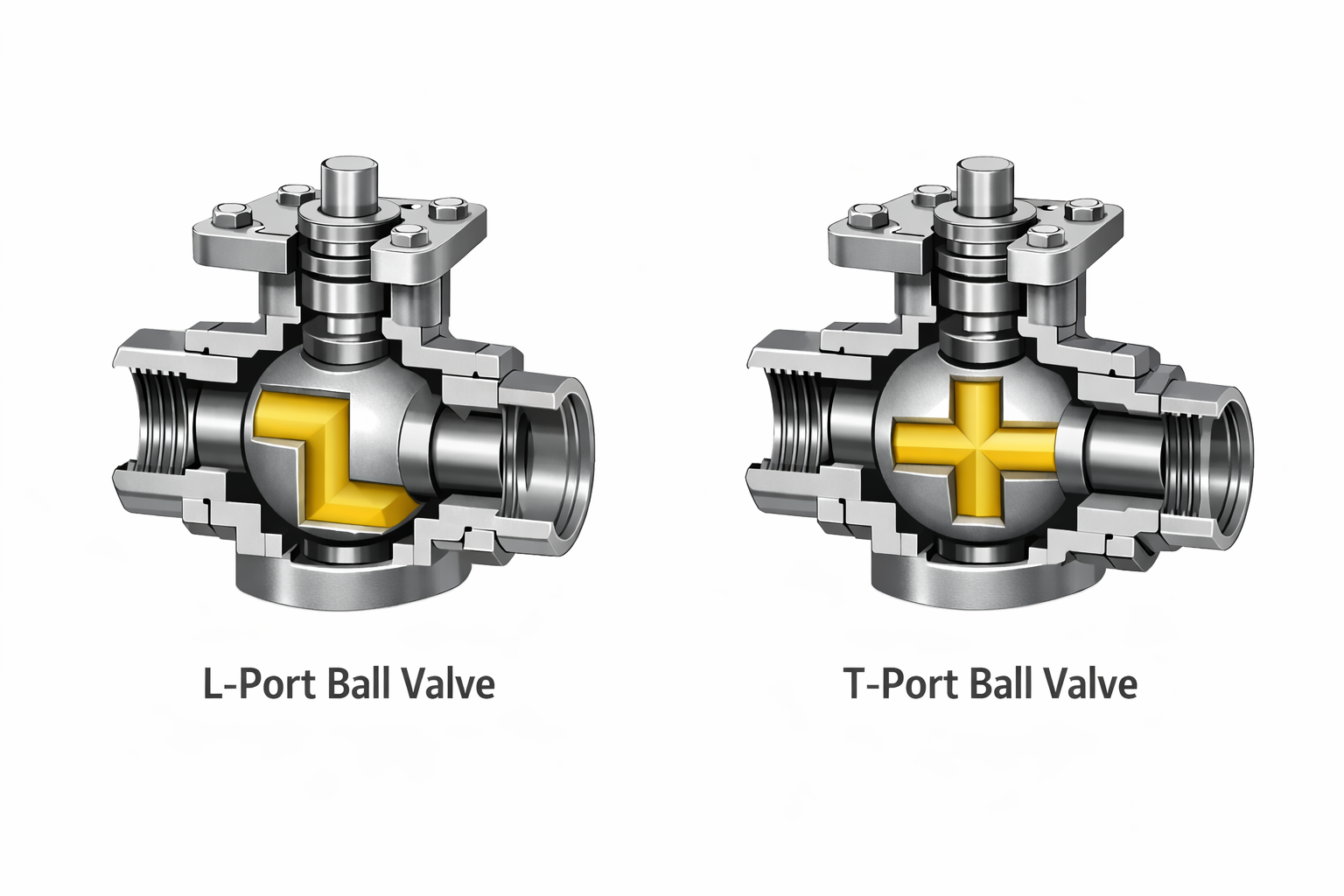

L-Port Ball Valve (Diverting Type)

The internal passage forms an “L” shape.

Flow characteristics:

- One inlet connects to only one outlet at a time

- The third port is always isolated

Typical applications:

- Flow diversion between two pipelines

- Duty / standby pump selection

- Switching process lines without mixing

Key engineering point:

An L-port valve cannot mix flows under any orientation.

T-Port Ball Valve (Mixing or Multi-Direction Type)

The internal passage forms a “T” shape.

Flow behavior depends on orientation:

- One inlet → two outlets

- Two inlets → one outlet (mixing)

- One inlet → one outlet

Typical applications:

- Chemical mixing

- Bypass arrangements

- Process systems requiring multiple flow states

Caution:

Incorrect orientation during installation can create unintended flow paths, leading to serious process issues.

What Is a 4-Way Ball Valve?

A 4 way ball valve has four ports and a more complex internal ball design, typically cross-drilled to allow multiple routing combinations.

Internal Design Characteristics

- Intersecting internal passages

- Tighter machining tolerances

- More complex sealing surfaces

Why 4-Way Ball Valves Are Specialized

In real industrial practice, 4-way ball valves are:

- Less common than 3-way valves

- Used only when system logic demands four-port routing

- Often specified to replace complex manifolds

Typical use cases include:

- Hydraulic systems

- Thermal oil circulation

- Specialized OEM skids

They should never be selected as a substitute for a 3-way valve unless the flow logic truly requires it.

Working Principle: 3-Way vs 4-Way Ball Valves

How Ball Rotation Controls Flow Paths

Both valve types operate on a quarter-turn (90°) principle, but:

- Each rotation aligns different internal passages with body ports

- Flow paths are fixed by ball drilling geometry

This predictable behavior allows easy integration with:

- Pneumatic actuators

- Electric actuators

- Limit switches and positioners

Practical Flow Examples

- Diverting:

A 3 way ball valve directs pump discharge to Line A or Line B. - Mixing:

A T-port valve combines two process streams into a single outlet. - Bypass:

A multi-port valve bypasses a heat exchanger during maintenance. - Cross-routing:

A 4 way ball valve switches flow between parallel circuits.

Key Differences Between 3-Way and 4-Way Ball Valves

Recommended visual: 3-way vs 4-way valve comparison image

| Parameter | 3-Way Ball Valve | 4-Way Ball Valve |

| Number of ports | 3 | 4 |

| Internal ball design | L-port or T-port | Cross-drilled |

| Primary function | Diverting / Mixing | Cross-routing |

| Application frequency | High | Limited |

| Design complexity | Moderate | High |

| Cost | Lower | Higher |

2-Piece vs 3-Piece Construction

Why Most Multi-Port Valves Are 3-Piece Design

For industrial service, 3-piece construction is strongly preferred.

Advantages:

- Center body removal without disturbing pipelines

- Easy access to ball and seats

- Simplified maintenance and refurbishment

- Lower lifecycle cost

For projects, chemical plants, and export applications, 3-piece construction is often mandatory.

Limitations of 2-Piece Multi-Port Valves

2-piece designs are generally limited to:

- Lower pressure ratings

- Non-critical service

- Clean, non-hazardous media

They are not recommended for demanding industrial applications where maintenance access is important.

Materials, Pressure Ratings & International Standards

Common Materials Used

Depending on service conditions:

- Carbon Steel (WCB, WCC)

- Stainless Steel (SS304, SS316, SS316L)

- Duplex & Super Duplex Stainless Steel

- Alloy steels for high-temperature service

Seat materials are selected based on:

- Media compatibility

- Temperature

- Pressure cycling

Pressure Ratings & Sizes

Typical ratings include:

- ANSI Class 150 / 300 / 600

- PN10 / PN16 / PN25 / PN40

- Custom ratings for OEM skids

Important engineering rule:

Always consider the weakest internal flow path, not just the valve body rating.

Applicable Standards

Export-quality industrial ball valves typically comply with:

- ASME B16.34 – Design & pressure-temperature ratings

- API 608 – Ball valve requirements

- ANSI / ASME flange standards

- DIN & EN standards for European projects

- Hydrostatic and seat leakage testing per applicable codes

Industrial Applications

Oil & Gas

- Flow diversion between processing units

- Bypass lines for filters and separators

- Offshore and onshore skid systems

Chemical & Petrochemical

- Media switching in batch reactors

- Controlled mixing applications

- Corrosion-resistant service

Water & Wastewater

- Filter backwash systems

- Distribution line selection

- Treatment plant flow control

OEM & Skid Manufacturers

- Chemical dosing skids

- Thermal oil systems

- Instrument air packages

EPC Projects

- Reduced piping complexity

- Faster installation

- Easier commissioning and maintenance

How to Select the Right Valve (Engineering Checklist)

Before finalizing selection, evaluate:

- Required flow paths (diverting vs mixing)

- L-port vs T-port logic

- Operating pressure and temperature

- Media compatibility

- Maintenance accessibility

- Automation requirements

Best practice:

Always prepare a flow logic diagram before specifying a multi-port ball valve.

Common Selection Mistakes

- Selecting T-port instead of L-port

- Ignoring internal flow orientation

- Underestimating pressure drop

- Choosing 2-piece construction for critical service

- Assuming all multi-port valves behave the same

Most commissioning failures trace back to selection-stage errors, not manufacturing defects.

Multi-port ball valves must be selected for function, not convenience.

Understanding the internal design and working principle of 3 way ball valves and 4 way ball valves is essential for safe, efficient, and reliable piping systems. When properly applied, they reduce system complexity, improve operational control, and lower long-term maintenance costs.

Not sure whether a 3-way or 4-way ball valves is right for your system?

Contact C-Way Engineering Exports for engineering review and application-specific valve selection support.