In industrial flow control, the butterfly valve remains one of the most widely used valve types for isolation and throttling applications. Simple in design yet highly efficient, butterfly valves are found in industries ranging from water treatment and HVAC to power generation, petrochemical, and oil & gas.

However, not all butterfly valves are the same. One of the most critical design differences lies in the type of seat — metal seated or resilient (soft) seated. The seat material directly impacts a valve’s sealing performance, temperature and pressure capabilities, corrosion resistance, and service life.

In this complete guide, we’ll compare Metal Seated vs Resilient Seated Butterfly Valves, explore their technical differences, and help you determine which type best suits your application.

Understanding Butterfly Valve Seating Design

Every butterfly valve consists of a body, disc, stem, and seat. The seat provides the sealing surface against which the disc closes, ensuring tight shut-off.

The seat type determines how the valve handles temperature, pressure, and media.

• Resilient seats use elastomers or soft materials that compress to form a bubble-tight seal.

• Metal seats rely on precision-engineered contact surfaces for sealing under demanding conditions.

Choosing the correct seat material is therefore essential to achieving leak-tight performance, longer service life, and reduced maintenance.

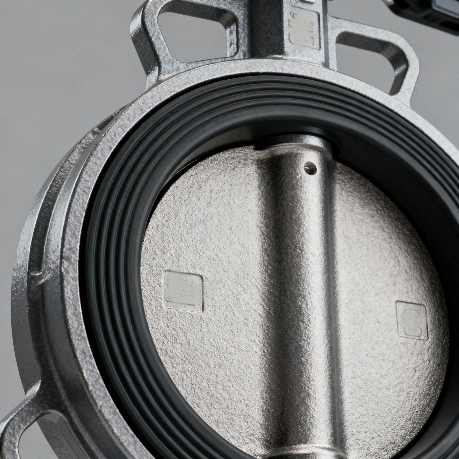

What Is a Resilient Seated Butterfly Valve?

A resilient seated butterfly valve (also called a soft seated valve)

uses an elastomeric seat such as EPDM, NBR, PTFE, or Viton.

The soft material deforms slightly when the disc closes, providing

a tight, bubble-proof seal even under low torque.

Key Features:

• Excellent bubble-tight shut-off

• Ideal for low to medium pressure systems

• Wide compatibility for non-corrosive and mild fluids

• Low operating torque and easy manual or automated operation

Typical Applications:

Resilient seated valves are commonly used in:

• Water distribution and wastewater treatment plants

• HVAC and chilled water systems

• Irrigation and general industrial piping

• Compressed air and non-corrosive gas lines

Common Seat Materials and Their Use:

| Seat Material | Temperature Range | Recommended Media |

|---|---|---|

| EPDM | -40°C to +120°C | Water, air, mild chemicals |

| NBR (Nitrile) | -20°C to +100°C | Oils and hydrocarbons |

| PTFE (Teflon) | -50°C to +180°C | Corrosive chemicals and acids |

| Viton | -20°C to +200°C | Steam, solvents, hydrocarbons |

Resilient seated valves are ideal where tight sealing and corrosion resistance are required under moderate temperature and pressure conditions.

What Is a Metal Seated Butterfly Valve?

A metal seated butterfly valve uses metal-to-metal contact between

the disc and seat. The seat and sealing edge are typically made of

stainless steel, hard-faced alloys (like Stellite), or high-performance

coatings (such as chromium carbide).

These valves are engineered for high-temperature, high-pressure, and abrasive service where soft seats would degrade quickly.

Key Features:

• Suitable for temperatures up to 600°C or higher

• Handles high-pressure and abrasive or corrosive media

• Offers longer service life under extreme conditions

• Designed for zero leakage performance in triple-offset design

Typical Applications:

• Steam and condensate systems

• Power generation and refinery units

• Chemical and petrochemical plants

• High-temperature gas and slurry pipelines

Metal seated butterfly valves are typically designed as double-offset or triple-offset valves, minimizing wear and ensuring reliable sealing performance even under thermal cycling.

Technical Comparison: Metal Seated vs Resilient Seated Butterfly Valves

| Parameter | Resilient Seated Butterfly Valve | Metal Seated Butterfly Valve |

|---|---|---|

| Sealing Type | Soft seal (elastomeric) | Metal-to-metal seal |

| Temperature Range | Up to 120°C | Up to 600°C or more |

| Pressure Rating | PN10–PN25 / Class 150 | PN40–PN160 / Class 300–600 |

| Sealing Performance | Bubble-tight (Class VI) | Industrial tight (Class IV–V) |

| Media Compatibility | Clean water, air, mild chemicals | Steam, slurry, abrasive or high-temp media |

| Maintenance | Easy seat replacement | Less frequent, more complex maintenance |

| Cost | Low initial cost | Higher cost but longer lifespan |

| Common Standards | EN 593, API 609 (Cat A) | API 609 (Cat B), ASME Class 300 |

In summary — resilient seated valves are best for clean, moderate service conditions, while metal seated valves excel in extreme industrial environments.

Application Suitability by Industry

| Industry | Recommended Type | Reason |

|---|---|---|

| Water & Wastewater Treatment | Resilient Seated | Corrosion-resistant, tight shutoff, economical |

| HVAC & Building Services | Resilient Seated | Compact, low torque, quiet operation |

| Oil & Gas / Refinery | Metal Seated | High temperature and pressure |

| Power Plants (Steam Lines) | Metal Seated | Handles thermal stress and high pressure |

| Chemical Processing | Both (depends on media) | PTFE lined or metal seated based on chemical type |

Material of Construction (MOC)

The performance and durability of both valve types also depend on the material of construction.

Common MOC Options:

| Component | Recommended Materials | Key Benefits |

|---|---|---|

| Body | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel | Strength, corrosion resistance |

| Disc | Stainless Steel (SS304, SS316), Duplex Steel, Aluminum Bronze | Resistant to corrosion, cavitation |

| Stem/Shaft | Stainless Steel, Monel, 17-4PH | High tensile strength |

| Seat | EPDM, NBR, PTFE (Resilient); SS316, Stellite (Metal) | Sealing and wear resistance |

| Coating | Fusion Bonded Epoxy (FBE), Nickel, or Chrome Plating | Enhanced surface protection |

Selecting the right MOC combination ensures compatibility with the media, temperature, and environmental conditions, extending service life and ensuring reliable operation.

Selection Guide: Which Butterfly Valve Is Right for You?

When choosing between metal seated and resilient seated butterfly valves, engineers should consider:

1. Operating Pressure & Temperature

o For systems up to 120°C → Resilient seated

o For systems up to 600°C → Metal seated

2. Type of Fluid (Media Compatibility)

o Water, air, or mild chemicals → Resilient seat (EPDM/NBR/PTFE)

o Steam, abrasive slurry, or corrosive gas → Metal seat

3. Sealing Requirements

o Bubble-tight shutoff → Resilient seat

o High-temperature industrial sealing → Metal seat (Triple Offset)

4. Maintenance Access & Budget

o Easy maintenance and cost-effective → Resilient seat

o Long-term reliability → Metal seat

Industry Standards & Compliance

To ensure safety, performance, and global compatibility, butterfly valves should comply with:

• API 609 (Category A & B) – Design and testing of butterfly valves

• EN 593 – European standard for industrial butterfly valves

• ISO 5752 – Face-to-face dimensions

• ASME B16.5 / EN 1092-1 – Flange connection compatibility

Using valves tested under these standards guarantees interchangeability, consistent performance, and long-term reliability.

Maintenance and Lifecycle of Butterfly Valve Seat

• Resilient Seated Valves: Require periodic seat inspection and replacement but offer quick, low-cost maintenance.

• Metal Seated Valves: Have higher upfront costs but longer service life, especially under high-cycle and extreme conditions.

Choosing the right type depends on your operational environment — not just price.

Summary: Which Is Best for You?

| Condition | Recommended Valve |

|---|---|

| Low temperature & pressure, clean fluid | Resilient Seated |

| High temperature & abrasive media | Metal Seated |

| Cost-sensitive general applications | Resilient Seated |

| Critical, high-performance industrial systems | Metal Seated |

In short —

Resilient seated butterfly valves provide economical, leak-tight performance for general use,

while metal seated butterfly valves deliver exceptional durability in harsh, high-temperature environments.

At C-Way Engineering Exports, we manufacture and export a comprehensive range of Metal Seated and Resilient Seated Butterfly Valves engineered to meet EN, API, and ASME standards.

Our valves are trusted across industries in the USA, Canada, UK, EU, UAE, Middle East, and Australia for their precision, durability, and reliability.

Whether you need a soft-seated valve for water applications or a triple-offset metal seated valve for steam and process lines, our team of engineers will help you select the right product for your system’s needs.