Triple Offset Butterfly Valves (TOBV) have become one of the most preferred High Temperature Butterfly Valve solutions

for high-temperature, high-pressure, and critical service applications across Oil & Gas, Petrochemical, Refinery, Power,

Chemical, Marine, and Offshore industries. As a leading Triple Offset Butterfly Valve manufacturer and exporter,

C-Way Engineering Exports delivers engineered flow solutions designed for demanding operations.

While standard soft-seated butterfly valves serve well in general flow isolation, their performance deteriorates rapidly

in severe service conditions due to seat damage, thermal distortion and friction between sealing surfaces.

This is where the Metal Seated Triple Offset Butterfly Valve stands out — engineered with a unique geometric

sealing mechanism, zero friction, and metal-to-metal fire-safe sealing that remains reliable under tough operating conditions

as required in API 609 Butterfly Valve specifications.

This article provides an engineering-oriented explanation of TOBV design, operation, sealing technology, and real-world advantages.

What Is a Triple Offset Butterfly Valve? (TOBV)

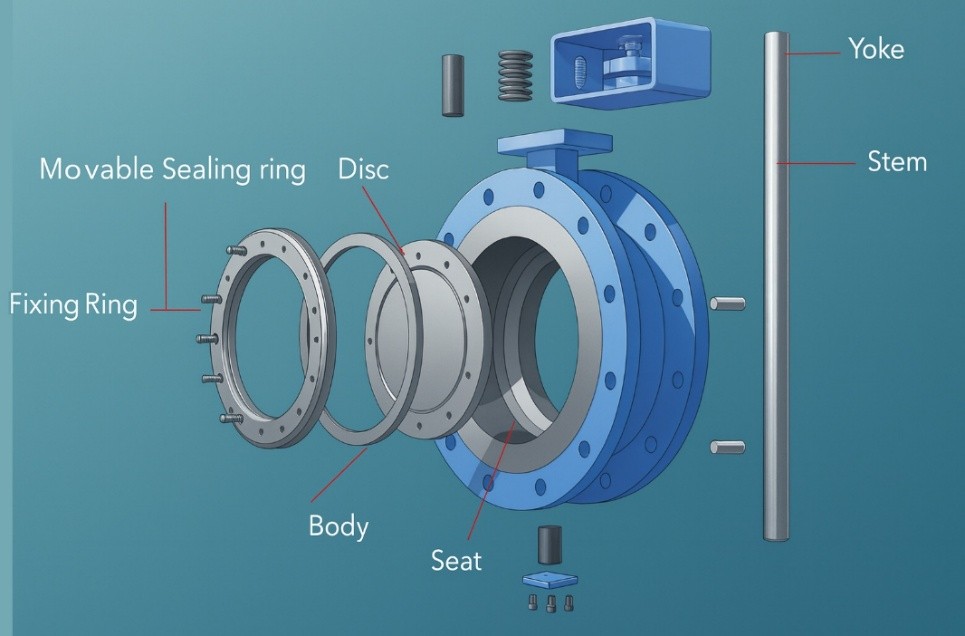

A Triple Offset Butterfly Valve is a quarter-turn, metal-seated isolation valve specifically designed for high-temperature, high-pressure, and critical pipeline service. Its name comes from three geometric offsets that eliminate friction, prevent seat wear, and ensure a bubble-tight metal seal.

The Three Offsets Explained

- First Offset – Shaft moved behind the sealing surface

The shaft is placed slightly behind the sealing surface, preventing the disc from rubbing the seat during rotation. - Second Offset – Shaft vertically shifted from pipeline centreline

A second offset ensures the disc rotates without interference, ensuring smooth and frictionless operation - Third Offset – Conical sealing geometry

The sealing surfaces of the disc and seat are machined into matching cones.

This conical profile creates a cam-like action, giving TOBV its hallmark benefits

• Zero rubbing during opening & closing

• Extended seat life

• Torque-seated metal seal

• Reliable operation under temperature fluctuations

These three offsets distinguish the Triple Offset Butterfly Valve from single and double offset designs and make it suitable for high-performance service.

Difference Between Single, Double, and Triple Offset Designs

| Valve Type | Seat Type | Sealing Performance | Service Range | Friction Level |

|---|---|---|---|---|

| Single Offset | Soft seat | Low | Low pressure, water service | High |

| Double Offset | Soft/Metal | Medium | Moderate pressure/temperature | Reduced |

| Triple Offset | Metal-to-Metal | High (Zero Leakage) | High-pressure / High-temperature / Critical | Zero friction |

Engineering Design of Triple Offset Butterfly Valves

Triple Offset Butterfly Valves are engineered to operate where other valves – especially soft-seated butterfly valves or conventional gate valves – typically fail.

Conical Metal-to-Metal Sealing Mechanism

The heart of TOBV design is its tapered conical seat and disc.

- Eliminates rubbing

- Prevents galling

- Achieves API 598 / ISO 5208 Rate A Zero Leakage

- Ensures long-term performance in steam and high-temperature service

Laminated Seal Ring Construction

Materials: Stainless steel, Graphite, optional Inconel

- Stainless steel

- Graphite

- Inconel alloy (optional depending on design)

This enables:

- Fire-safe operation

- Thermal expansion absorption

- Tight shut-off at both low and high pressures

Body, Disc & Shaft Materials

- Carbon steel (WCB)

- Stainless steel (CF8, CF8M)

- Duplex/Super Duplex

- High-temperature alloys (Inconel, Monel, Hastelloy)

These material combinations increase corrosion resistance and temperature stability.

Temperature & Pressure Ratings

Typical TOBV ratings include:

- ASME Class 150, 300, and 600

- Temperature capability from -50°C up to +600°C depending on material

- Compliance with API 609 Category B and ASME B16.34

High-volume keywords included: API 609 butterfly valve, high temperature butterfly valve, metal seated valve.

How Triple Offset Butterfly Valves Operate

TOBVs operate on a quarter-turn principle similar to ball valves and high-performance butterfly valves, but with an advanced sealing action.

Torque-Seated Operation

Unlike soft-seated valves (which rely on elastic deformation), a TOBV achieves sealing through:

- A controlled angular torque

- Disc-to-seat compression

- Cam-like sealing engagement

This ensures reliable bubble-tight shutoff even under high differential pressures.

Zero-Friction Principle

Due to the three offsets:

- Disc only contacts the seat at the final moment of closing

- No scraping or rubbing

- Minimal seat wear

- Lower operating torque

- Smaller actuator size requirements

Fire-Safe Performance

Because TOBVs use metal-to-metal sealing, they operate safely even when:

- Elastomers burn out

- Process temperature spikes

- Fire-safe certification is required

Why Choose Triple Offset Butterfly Valves for Critical Service?

Triple Offset Butterfly Valves outperform other valve types when safety, reliability, and precision sealing matter most.

High-Temperature Capabilities

TOBVs maintain sealing integrity at temperatures where soft seats would immediately fail:

- Superheated steam

- Hot hydrocarbon lines

- Fired heater outlet lines

- Refinery process streams

Zero Leakage (API 598 / ISO 5208 Rate A)

Metal-to-metal conical sealing provides true zero leakage, even under:

- Thermal expansion

- Pressure surges

- Pipeline vibration

Superior Performance vs Gate Valve and Ball Valve

Compared to Gate Valves:

- Much lighter

- Faster operation (quarter turn vs multi-turn)

- Smaller footprint

- Lower maintenance

Compared to Ball Valves:

- Lower cost at large diameters

- More compact

- No cavity for fluid entrapment

- Better high-temperature sealing

This makes TOBV the preferred choice for EPC & Oil & Gas isolation valves, critical pipeline control and severe service applications requiring zero leakage performance.

Applications of Triple Offset Butterfly Valves

TOBVs are widely used in severe, high-temperature, and high-pressure pipeline systems.

Oil & Gas Production & Refining

• Hot hydrocarbon service

• Emergency shutdown (ESD)

• Crude oil and gas isolation

Petrochemical & Chemical Plants

• Condensate

• Polymer service

• Acidic and corrosive media

Power Generation (Thermal & Combined Cycle)

• Superheated steam

• Boiler feedwater isolation

• Turbine bypass systems

Marine & Offshore Platforms

• High-pressure seawater lines

• Compact space applications

Pulp & Paper, Mining, and Steel Plants

• High-temperature slurries

• Harsh media where soft seats fail

Installation Guidelines for Triple Offset Butterfly Valves

Improper installation is one of the primary causes of TOBV performance issues.

Correct Actuator Sizing

Triple Offset Butterfly Valves require:

• Accurate torque calculation

• Proper actuator selection (pneumatic, electric, or hydraulic)

Alignment and Flange Compatibility

• Compatible with ASME B16.5 / B16.47 flanges

• Pipeline must be aligned to avoid disc interference

Avoiding Common Installation Errors

• Over-torquing flange bolts

• Installing without disc travel check

• Choosing incorrect fail-safe mode

Troubleshooting Triple Offset Butterfly Valves

Even with robust design, some issues can arise if not installed correctly.

1. Leakage at Metal Seal

Causes:

• Misalignment

• Seat damage

• Incorrect closing torque

Solution:

• Re-align pipeline

• Check actuator calibration

2. High Operating Torque

Causes:

• Bearing wear

• Deposits on sealing surface

Solution:

• Clean seat area

• Replace bearings when required

3. Disc or Seat Damage

Causes:

• Abrasive media

• Thermal shock

• Foreign particles

Solution:

• Add filtration

• Use hard-coated disc and seat

Triple Offset vs High-Performance Double Offset Butterfly Valves

| Feature | Double Offset | Triple Offset |

|---|---|---|

| Seat Type | Soft/Metal | Metal-to-Metal |

| Temp Resistance | Medium | Very High |

| Leakage Rate | Low | Zero Leakage |

| Friction | Reduced | Zero |

| Application | General industrial service | Critical service |

If the service demands zero leakage, fire-safe sealing, and high temperature stability, TOBV is the clear choice.

Conclusion: Why Triple Offset Butterfly Valves Are the Smart Choice for Critical Applications

Triple Offset Butterfly Valves combine the advantages of:

• Zero-friction sealing

• Metal-to-metal fire-safe design

• High temperature & high pressure capability

• Compact, lightweight structure

• Reliable operation in severe service

Their engineering strength and performance advantages make them ideal for Oil & Gas, Petrochemical, Power, Chemical, and Marine industries looking for long-term, maintenance-free isolation solutions.

With global demand increasing for API 609 Category B high-performance valves, TOBVs will continue to lead the market wherever safety and reliability matter most.

Looking for Triple Offset Butterfly Valve suppliers engineered for high-temperature and severe service? Contact C-Way Engineering Exports, a global exporter of high-performance metal seated butterfly valves for certified, custom-built TOBV solutions.